You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Prototype fillet knife

- Thread starter Chris Railey

- Start date

EdCaffreyMS

"The Montana Bladesmith"

Looks good! On the next one, I'd get rid of that bevel running down the blade.....the way I do it is with a convex grind that "fades out" near the spine. I learned that trick for fillet knives after making a few and testing them while fishing with a friend off Vancouver Island...... where we cleaned well over 100lbs of fish per day, over a two week period. Best fishing I have ever experienced!

The knives I made/tested were all 9-10" blades..... I found out the first day my knives were woefully undersized...... most of those fish were more like butchering a deer than "cleaning fish"

This was one morning's catch......

A 34lb King...

And OH!!! I FOUND NEMO!!

The knives I made/tested were all 9-10" blades..... I found out the first day my knives were woefully undersized...... most of those fish were more like butchering a deer than "cleaning fish"

This was one morning's catch......

A 34lb King...

And OH!!! I FOUND NEMO!!

Chris Railey

Well-Known Member

So do you grind the whole thing on a slack belt or do you flat grind and sharpen with a convex edge?convex grind

Chris Railey

Well-Known Member

Great fish by the way.

John Wilson

Well-Known Member

Great job on those!

I’m with Ed on the bevel. Thin is in for fillet knives. I do a full flat grind that tapers to the point and convex the edge.

I’m with Ed on the bevel. Thin is in for fillet knives. I do a full flat grind that tapers to the point and convex the edge.

Bruce McLeish

Well-Known Member

OK , since I'm still so new at this ... Lucy , please 'splain it to me this convexing the edge. Thanks

BJ

BJ

John Wilson

Well-Known Member

OK , since I'm still so new at this ... Lucy , please 'splain it to me this convexing the edge. Thanks

BJ

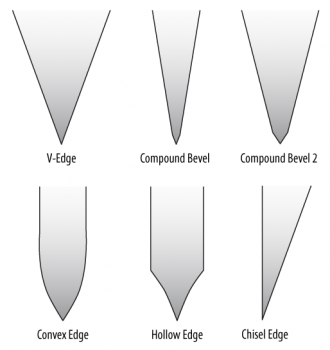

This drawing is meant for axes, so imagine everything being much thinner.

A typical secondary bevel (the sharp edge bevel) is a secondary V-shape known as a compound bevel. A convex edge is a smooth, round transition from the primary bevel to the cutting edge. This leaves a lot of meat behind the cutting edge to support it. On really thin knives this is a great way to make as strong an edge as possible. The blade is so thin on a knife that it’s not going to add much in the way of cut-resistance (pushing a fat wedge into a thin cut). On softer materials (food) the convex edge actually parts the food like water and reduces contact between the food and the blade.

You get a convex edge by grinding on the slack belt. By slack belt, the area between the contact wheel and the platen or the area of the belt just before the wheel work well because they are stiff enough to get a good grind, but have no hard backing so these area still deflect enough to give you the convex shape.

A person can convex the whole bevel on a very small blade. On a big blade this would take a month of Sundays and wouldn’t really help you. The tiny little cutting edge cuts, not the whole bevel. There’s no value in a true axe grind for a knife, in my opinion. A flat grind will give you a thinner blade. Ground flat on both sides to a true wedge is called a “zero grind” because there is zero secondary bevel. Most knife blades are too thin to hold this extreme of an edge. The secondary bevel fattens that edge up a bit, but it’s still way thin enough to be razor sharp.

Last edited:

Chris Railey

Well-Known Member

Yeah mine is a zero grind, it just sort of ended up that way. Next time will be a full flat grind with a convex edge. This one does not quite have the flex I wanted. A higher grind should fix that. John, would I do a regular flat grind to the spine but leave just a little extra on the edge (not a zero grind) to convex to an edge?

Bruce McLeish

Well-Known Member

John, thanks for the explanation. It actually makes sense to this old farmer-wanna-be-knifemaker.

John Wilson

Well-Known Member

Yeah mine is a zero grind, it just sort of ended up that way. Next time will be a full flat grind with a convex edge. This one does not quite have the flex I wanted. A higher grind should fix that. John, would I do a regular flat grind to the spine but leave just a little extra on the edge (not a zero grind) to convex to an edge?

I basically full flat grind it to a zero edge. Now we have a perfect triangle, right? A pure wedge and the cutting edge is the apex of that downward pointing triangle. The base of the triangle is already only .070 at the thickest part, and gets thinner as we follow the spine to the tip. So that cutting edge is as thin as thin can be. That won’t hold up.

Then i convex the edge to fatten it up enough to be stable. A zero edge on .070 steel is paper thin. By convexing it, yes it makes it a little less sharp, (like all secondary bevels do) but it’s necessary or else the edge would fail pretty quick.

Chris Railey

Well-Known Member

That makes sense John. I will do the next one that way.

Von Gruff

KNIFE MAKER

I keep getting updates from the guy I made one for about how many fish he is doing and still has the original edge without having been touched. I do a full flat grind on 1.5mm 12C27 at the sharpening notch so it has distal taper and very thin and fexible toward the tip. The edge is a secondary bevel rather thn a conves though.

John Wilson

Well-Known Member

I think if the geometry of the blade is good, the type of edge you put on it is more personal preference than anything else.

Chris Railey

Well-Known Member

Something else I was thinking: It does matter if the filleter goes through ribs or around the ribs. Through ribs means a convex edge. Around ribs can use a secondary or zero bevel. I fillet around ribs never through. However, I want more flex from the knife so I will do another with full flat grind. Well, that and the fact that the end of the handle looks like a turd so I hate it. I really like a zero or secondary angle bevel because I can touch it up in the field easily. Convex edges are harder for me to sharpen away from a belt grinder.

John Wilson

Well-Known Member

This is why it’s good to offer several sizes and styles. I sell a 6 inch and a 9 inch. For big honking saltwater fish the 9 inch with some stiffness built in is necessary to cut through ribs. But you don’t want a sword for smaller delicate fish. The super flexy 6 inch is much better suited.

John Wilson

Well-Known Member

Oddly enough, I sell quite a few fillet knives as kitchen knives. They are seriously one of the most versatile knives for trimming meats, boning poultry and slicing melons.