SHOKR

Well-Known Member

Hi all

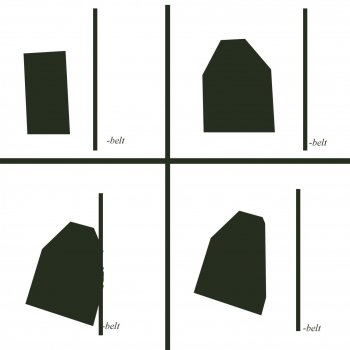

Im new to knife making and i have trouble sticking to the edge thickness before sharpening

Translation: i mark the edge, but i either go past the lines and end up with thinner edge, or to counter that i end up not reaching the edge and with a thicker edge

How do you guys do it?

Thanks

Im new to knife making and i have trouble sticking to the edge thickness before sharpening

Translation: i mark the edge, but i either go past the lines and end up with thinner edge, or to counter that i end up not reaching the edge and with a thicker edge

How do you guys do it?

Thanks

Last edited: