Gliden07

Well-Known Member

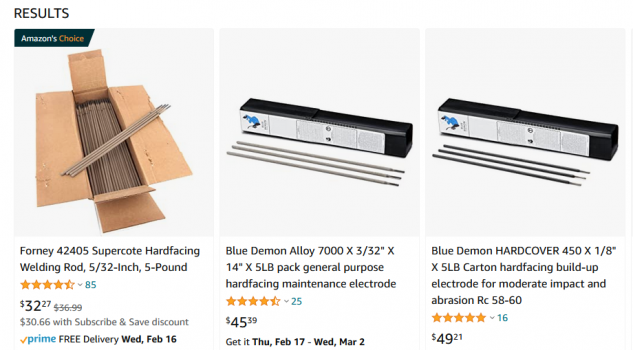

I got a post vice at a garage sale cheap. There is a problem with it. The jaws don't meet when clamped. Wanted to know how I should fix, fill in with weld (hard face or a standard rod) or grind/ mill flat. Maybe a boat anchor?? LOL!!

PS The vice is complete no missing parts.

PS The vice is complete no missing parts.