Von Gruff

KNIFE MAKER

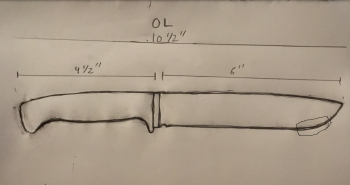

Overll that is a good blade design with the handle only needing the bottom lone altered to make that a very usable knife. Take the "peak" out of the underside and replace it with a light convex curve and you will be surprised at how much that changes the feel in hand. Lay your hand flat on the table and look at the curve that shows the differing lengths of your main finger joint (first joint) and use this curve as a guide for the handle underside as that is the griping shape your hand makes.I like the way it looks, simple and clean. The hump for the finger choil might push your fingers back towards the heel some, making the handle feel shorter then it is. Make a template and see how it feels. Some times it looks good on paper but in real life it is uncomfortable.

View attachment 66944

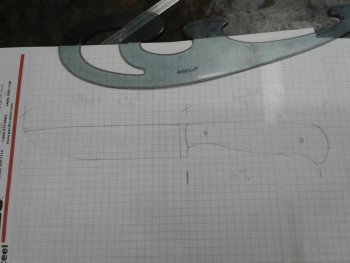

Here's one I designed had approval from the customer. We were both excited. I made a template, and it was just to uncomfortable in the hand to proceed.