Mark Barone

Well-Known Member

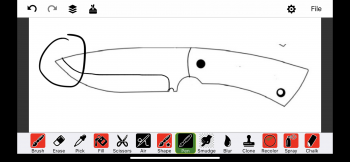

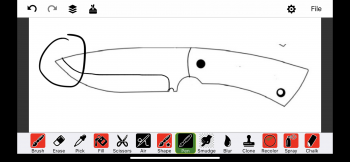

Probably a question that is often asked...As I move the blade against the platen I know the tip of the blade needs a little finessing to get the bevel to stay the same height. Is it just slowing down the stroke at the end so more grinding time happens or do I give it that little “pull back”? It seems my pull back always results in burning the tip. Not sure what I’m doing wrong. I use a jig.