The coolest knife in my opinion.

Here's a few from my collection.

we'll take three different OTF knives

Open them up and take them apart.

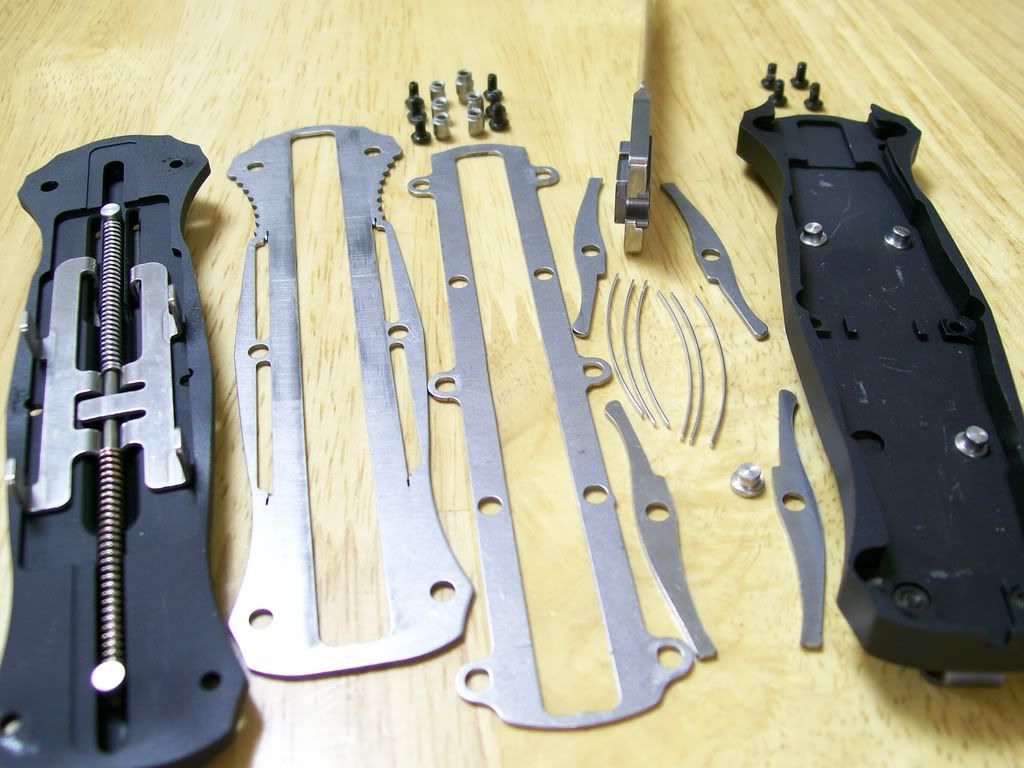

The Top Auto taken apart.

The Super Auto in pieces.

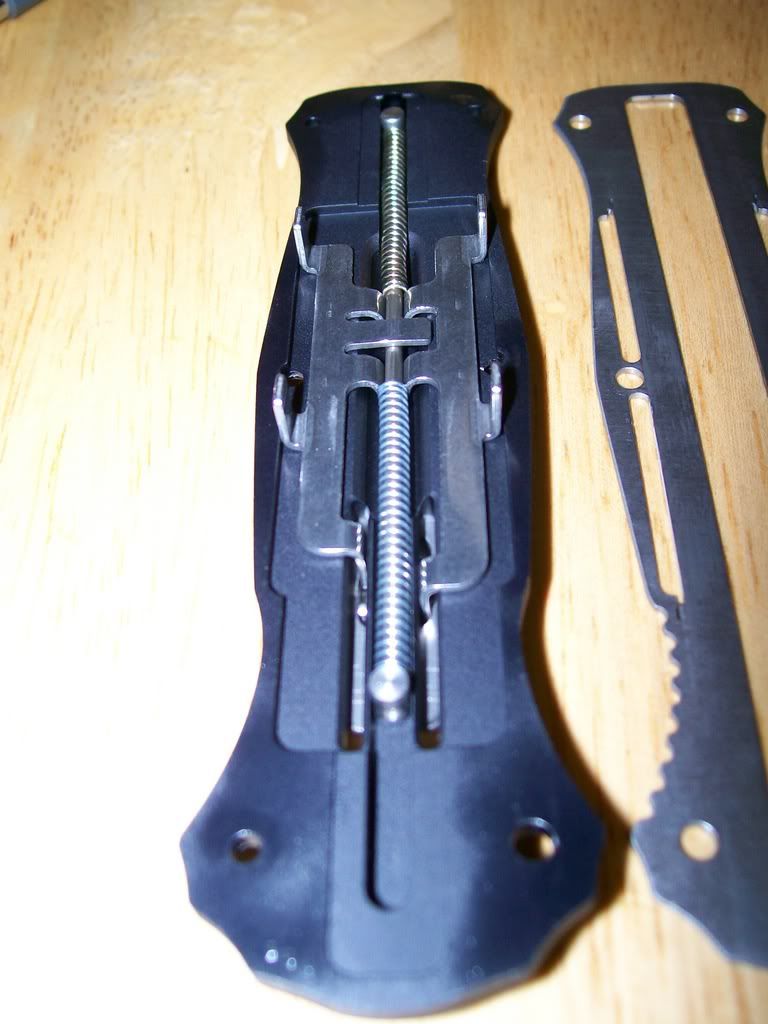

The Harkins Triton opened up.

All the Double Action Out-The-Front knives work the same, they are just designed and built a little different.

Here's how it's made...

The blade is in a channel and slides freely from open position to closed.

The blade has a pin in the back end, this pin rides in a slot and keeps the blade from shooting out when the pin hit the end of the slot.

Above the blade is a motion bar. This motion bar has two lock tabs, one one each side on each end, a tab for the thumb switch, and a kicker spring.

The kicker spring has a tab attached on each end with the back end being a little longer. This spring is stretched accross the motion bar tightly.

On each side at each end is a locking tab/lever, seems like each knife does this part a little different, but it's all a side lock mech of some kind.

And here's how it works...

When the knife is closed the blade is locked by the back lock lever and the motion bar is in the back position with spring tight.

To open, move the button forward and the motion bar slides forward, streching the sping more and increasing tension.

Push the button far enough and the side lock tabs will slide against/over the back lock lever moving it into the open position releasing the blade.

The tabs on the spring are what kicks the blade open and closed.

The back spring tab kicks against the back of the blade opening the knife.

The blade is now locked open by the front lock lever and the spring is again streched.

To close, move the button back, this reverses the process.

The shorter front spring tab rides over the blade and kicks against the blade pin to close. Same function to open the knife as is to close.

The triton is really designed different. With no handle scale to remove, everything is attached to the upper handle piece. The side locks on most are now positioned above the blade. This knife is built SUPER strong!! Feels like it's biult like a gun.

I think the button has about a 10lbs pull. The difference between $40 knife and a $400 knife 8) I love my Triton :twisted:

Here's a pictue of a Pirana taken apart.

Same parts just put together different. Looks like they have a double lock -two front/open lock bars and two back/closed lock bars. I just don't see what would be 'unlocking tabs' on the motion bar. I don't own one yet, but if I get one I will of course tear it apart and check it out.

It's a great design, one of the best. Unfortunately, I have looked and nobody in the switchblade community has any info on who designed it or when. We don't know the first maker or the first knife. Seems like it might have been in the 1950's. I've found it difficult to research foreign patents.

What I like best, other than the fact that it's just the coolest thing to see a blade pop back and forth, it's the fact that every OTF knife I have is built different, sometimes very different. And that's great! No matter how you put it together it should work because it's a simple design. Sure, building one from scratch would take a bit of trial and error getting everything to slide right and getting the spring tension correct. But I have tiny little keychain OTF knifes. If they can take the design and make it crappy out of plastic 2 inches long and make it work I would think any size-any materials would work. It's just a matter of a good design, but the basic principle is genius! I think a forearm weapon could be built with this design modified a bit.

Make a blade slide and kick it back and forth with locks...simple.

<object width="425" height="344"><param name="movie" value="http://www.youtube.com/v/fJWV7W8SdlY&hl=en_US&fs=1&"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/fJWV7W8SdlY&hl=en_US&fs=1&" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="425" height="344"></embed></object>

More pictures of the insides of Out-The-Front Automatic Knives!!!

Makora:

Scarab:

UT6/UTX70:

UT7 (note: same as UT6 except the blade is removable):

Size comparison. From left: Piranha Excalibur, DKW Sandshark, Infidel, ProTech Godfather.(note:Godfather is not OTF but side opening)

The Infidel

Opening the Infidel. Held together with 12 torque screws, 6 on each side.

All hardware is held in each half. Sears in bottom half (belt clip side) *pictured on left*. Springs and firing catch housed in top half (button side) *pictured right*.

Complete breakdown

Closer look at the very thin sears, (barely 1 mm thick), and the 6 leaf springs that hold the sears out to lock the blade, each are less then a 1/2 mm thick.

Credit to this one goes to nameless over at JD

DKW Sandshark and Piranha Excalibur. Is there a bit of Sandshark engineered in the Excalibur?

I have read rumors about this, more than a few times, so I decided to take a closer look.

The knives do seem strangely similar in appearance but what about the blood & guts? Here are some pictures of both, you make your own decisions. I will say this much, I found a new respect for the Piranha. It may not be as tough as the Shark, but as far as OTF's go, it is very impressive.

Both side by side before opening

Opened, Shark is held together with a very nice 11 screw set up (4 on one side, 7 on the other) The Piranha has 6, all on one side.

Both have a very sturdy blade rail channel. Sandshark has three rail channels set inside the handle/housing(1 large center, 2 smaller on each side). Excalibur has one channel (1 large center). Shark has 13 blade to frame contact points (4 "H" blade points, 3 main blade rail pin points, *center pin goes through the blade contacting opposite side making 1 more contact point*, 2 smaller blade rail/adjuster screw contact pins, 3 frame to blade adjuster screws). Excalibur has 5 contact points (4 "H" blade points, 1 blade rail pin)

Note both stop bars (seen as long horizontal silver pins or bars, near the top of housings), the Excalibur's stop bar (right) is set deeper in the frame ( a nice method to hold the blade with out using extra pins). The Shark's stop bar (left) is set at the very top of the frame, blade is also held very tight because of the extra blade rail pins (3 large main, 2 smaller ) and then the over kill of 3 more adjuster screws (seen in picture as the 3 small silver spots at the top of the Sharks frame Left)

Closer look. Note the "notch" cut at the bottom of the Excalibur's blade (right), and also the "hole" in the blade. These are the contact spots for the firing catch. The Hole is where one of the two firing catches contact the blade, allowing the blade to fire in. The "notch" position fires the blade out. The Sandshark uses the number 2 pin for this same DA (double action) function.

Close look at the Sharks blade rail pins, 5 in all. The First pin (closest to tip of blade) is also used as the front stop pin, The 3 pin is also used as the rear stop pin, Middle or 2 pin is also used as the DA firing pin. Another very nice SandShark blade feature, is the two, much smaller, round blade pins that can just be seen in the picture as two shiny spots left & right of the 2 pin. These two smaller rounded balls or pins are set in the blade and travel down the two small rail channels, seen on either side of the large center main channel. This is where, two of the three frame adjuster screws, make contact when the Sharks blade is in the "out" position.

Sharks center blade rail pin, Note how it extends to the other side of blade. The Excalibur uses one main blade pin, but it is deep and because of the way the blade is set a little deeper when locked out, it still holds strong & tight.

Side by side of the firing mechanisms, both are almost identical. The only real difference is the Shark being larger. Both have a large center type spring (forward and rear brass blade firing catch) held together with 6 screws sandwiched between two pieces of T-6 aluminum. The Piranha may even have a very small lead here because of the over sized quad blade lever locks (sears) that are held in place with center pins that go into the frame. The Sharks lock levers are half the size and are held in place with a bonding agent, very strong, but I would have liked to have seen a through pin (as seen in Excalibur), instead of the bonding agent holding the Sharks sear levers. It almost seems that the Piranha was the next generation on this one, single, issue. If there is any link between Shark and Piranha, this is where it seems likely, if at all. (seen in picture as the 4 metal bars at each corner, just sticking up) Piranha on left: Sandshark on right.

The Piranhas lock levers (sears) have a leaf spring to hold the levers at the ready. One leaf spring on each side

Sharks levers, held at the ready with 4 coil springs.

Complete break down of firing mechanism (Excalibur). Sandshark break-down & parts are basically the same, but in no way interchangeable. These pictures are just to give you a complete opened view of the closed firing mechanisms shown above.

How the sears hold the blade inside, ready to fire. Pushing the button forward drops the sears allowing the blade to fire forward. The center notch at the back of the blade is where the center spring catch engages the blade.

Inside view of blade in the locked-out position. The sears pop-up behind the blade, locking it in the out position.

Video link, No sound: Assembly of the firing mech. Click on picture

<embed width="448" height="361" type="application/x-shockwave-flash" wmode="transparent" src="http://i155.photobucket.com/player.swf?file=http://vid155.photobucket.com/albums/s289/namelless/ExcaliburfiringMech-2.flv">

Bottom line, the Piranha is a good OTF but nothing compares to the DKW Sandshark for shear strength, power, and cost. It fires like a Tank and just as strong, locks out to rival a fix blade.

This Video, all though old, says it all:

http://videoknife.com/sand/sand.wmv

I guess this would fall under 'throwing the dog a bone'....

I'll post more when I get a chance, I have a ton on my forum.