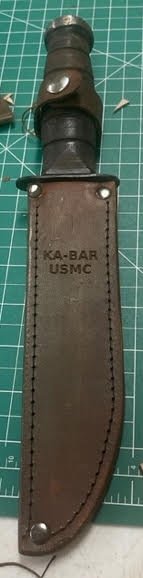

Well Chris did it again - cost me money. After reading his thread on the Ortur Laser Master 3 and how well it engraved metal I ordered one also. Got it yesterday and must say I'm well pleased with how well it works. Here's on example how well it engraves 64 Rc 26C3 metal:

I'm still learning, not only the laser but also LightBurn program. The two guys who own and write the program sure do a good job. So far, I'm impressed with the program. I didn't even try the freebie program that comes with the laser, just downloaded LightBurn.

Chris - thank you for the thread. 10 watts of laser power, as well as the tiny dot used to condense the power does a pretty good job.

I have lightly sanded with 1200 grit, and really scrubbed with scotchbright and so far the etch is holding up good. The etch isn't very deep, but you can feel it and the engraving stayed dark even after hard scrubbing. Those two dots to the left of the hen - not sure what those are. Most likely in the surface before I did the engraving.

I'm still learning, not only the laser but also LightBurn program. The two guys who own and write the program sure do a good job. So far, I'm impressed with the program. I didn't even try the freebie program that comes with the laser, just downloaded LightBurn.

Chris - thank you for the thread. 10 watts of laser power, as well as the tiny dot used to condense the power does a pretty good job.

I have lightly sanded with 1200 grit, and really scrubbed with scotchbright and so far the etch is holding up good. The etch isn't very deep, but you can feel it and the engraving stayed dark even after hard scrubbing. Those two dots to the left of the hen - not sure what those are. Most likely in the surface before I did the engraving.