Just completed knife number five, five more too go (before tomorrow *rolls eyes*)

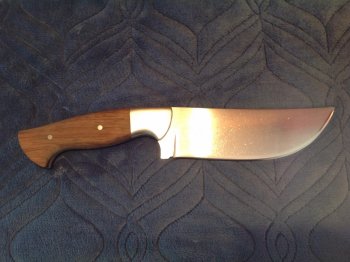

This is a 12" 1084 recurve with SS bolster (mat finish) bubinga handle and stone washed blade.

This knife has been in the works for a while now in one form or another. I've made several experimental versions that I didnt like, they all ended up in my huge box of rejected blades.

This one turned out GREAT! Imo as far as completed knife number 5 in my career goes

It's plenty tough enough... As it cut a chunk out of my buffer (happens often) not a scratch on the blade.

I'ts sharp enough to shave with, feels good in the hand and is well balanced.

I tried a few new techniques on this one... The stone wash finish. That was going well until my father found it tumbling in his clothes dryer and almost lost his mind.

The 1/16 bolster pins pain in the butt! Switching to a slower epoxy helped a lot!

With some help i've finally managed to get the hang of nearly invisible pins... Now it's a matter of practice.

I really like this blade but it has two flaws i'm still trying to get the hang of.

The first is: I cant seem to get a clean tight seal between the bolster/handle scales and the blade... Looking at the spine you can see ugly gaps. Peening helps some... But there must be a better trick too it. I see so many blades that the bolster is so tight it looks like one piece.

I'm using pins and epoxy then peening and smaking the heck out of it then clamping with C clamps.

I'm considering perhaps some sort of hydraulic vise? More pressure to the bolster.

The parts are flat... As far as I can tell anyway.

The other issue is sharpening... I use the belt grinder and water to keep it cool then strop on the buffer. Gets a whicked sharp edge but it makes a terrible looking edge bevel. All wavy... Kind of like an edge on a cheap machete also the buffer makes an ugly shiny line that ruins the mat finish.

also the buffer makes an ugly shiny line that ruins the mat finish.

Any thoughts or ideas/tips advise would be appreciated!

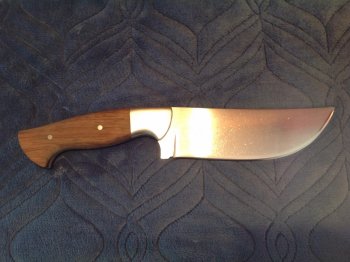

This is a 12" 1084 recurve with SS bolster (mat finish) bubinga handle and stone washed blade.

This knife has been in the works for a while now in one form or another. I've made several experimental versions that I didnt like, they all ended up in my huge box of rejected blades.

This one turned out GREAT! Imo as far as completed knife number 5 in my career goes

It's plenty tough enough... As it cut a chunk out of my buffer (happens often) not a scratch on the blade.

I'ts sharp enough to shave with, feels good in the hand and is well balanced.

I tried a few new techniques on this one... The stone wash finish. That was going well until my father found it tumbling in his clothes dryer and almost lost his mind.

The 1/16 bolster pins pain in the butt! Switching to a slower epoxy helped a lot!

With some help i've finally managed to get the hang of nearly invisible pins... Now it's a matter of practice.

I really like this blade but it has two flaws i'm still trying to get the hang of.

The first is: I cant seem to get a clean tight seal between the bolster/handle scales and the blade... Looking at the spine you can see ugly gaps. Peening helps some... But there must be a better trick too it. I see so many blades that the bolster is so tight it looks like one piece.

I'm using pins and epoxy then peening and smaking the heck out of it then clamping with C clamps.

I'm considering perhaps some sort of hydraulic vise? More pressure to the bolster.

The parts are flat... As far as I can tell anyway.

The other issue is sharpening... I use the belt grinder and water to keep it cool then strop on the buffer. Gets a whicked sharp edge but it makes a terrible looking edge bevel. All wavy... Kind of like an edge on a cheap machete

Any thoughts or ideas/tips advise would be appreciated!