opaul

Well-Known Member

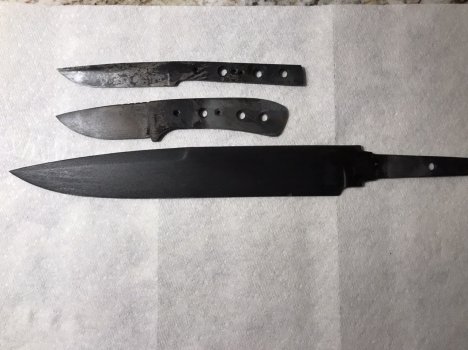

I got started on Chris’s knife today. He got a Bowie from me in the last one I participated in - but no Bowie this time. I know Chris likes to hunt and camp so I thought this knife would be a nice companion on those adventures. The steel is 52100 and construction will be a’3 piece knife’. Following are photos with comments.