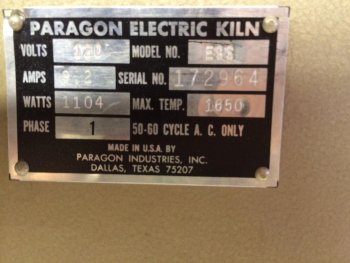

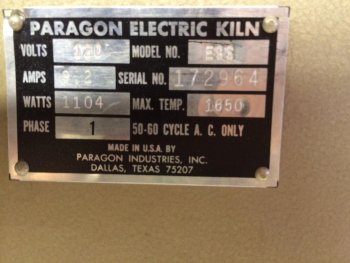

I bought this off of ebay for $175 on Monday and got it on Wednesday. I heated up a blade I had made for practice that was off of a giant old sawmill blade I bought at a garage sale. It took about 30 mins to get to non-magnetic. It has no control, just plug it in and let it heat up. The spec label says the max temp is 1650. Any tips or advice on using it to its max potential and a way to regulate the temp would be greatly appreciated. I know nothing about kilns so use words of 3 syllables or less, please! :biggrin::biggrin::biggrin: