You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Next step

- Thread starter norseman

- Start date

Randy Lucius

Well-Known Member

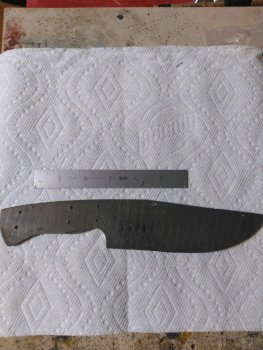

Hi Vern. I usually grind the bevels before heat treat. Except if I’m working with thin stock. Made some .080 AEBL steak knives. Ground all of those after heat treat to avoid warping. Most steels I think it’s a personal preference. Some guys grind before some grind after heat treat. What steel are you working with? That’s a good looking profile.I am pleased with my profile, going with brass bolsters and wood handle with brass pins. Is it better to Grind the blade before hardening?

Thanks Vern

Randy Lucius

Well-Known Member

Was it made by Poshland?I confess I don't know what steel it is, bought a piece off Amazon - BLD-54 from Poshland Industries, ladder pattern. It is fairly hard to cut and it all looks tight along the grinds so far.

Randy Lucius

Well-Known Member

I’m in the shop tonight not sure about Poshland steel. When I get a few minutes I’ll look them up. I usually stay away from Amazon or EBay for steel, especially Damascus. You never know what you’re getting. Always buy known steel from a quality vendor. It pays for itself. Steel is cheap, elbow grease is expensive.

You’ll be ok. The Poshland forge welded steel is typical 1095/15N20, albeit WAY overpriced, will work as any other forge weld stuff.

Everyone knows my opinion of forge weld steel, but it does look nice.

My take is always grinding the bevels AFTER heat treating! My reason on this being it gives the blade the “Optimum” conditions for a perfect heat treat. With the steel at the same thickness throughout, it will heat up & cool down at the same rate.

I will say though, I don’t use simple carbons. I use only CPM Tool & high speed alloys, which require MUCH higher heat, and plate quenching. The plate quench was my main criteria. The lower heat & oil quenching of simple carbons are certainly more forgiving. Although I can argue it’s still giving it the ideal conditions by grinding after.

Everyone knows my opinion of forge weld steel, but it does look nice.

My take is always grinding the bevels AFTER heat treating! My reason on this being it gives the blade the “Optimum” conditions for a perfect heat treat. With the steel at the same thickness throughout, it will heat up & cool down at the same rate.

I will say though, I don’t use simple carbons. I use only CPM Tool & high speed alloys, which require MUCH higher heat, and plate quenching. The plate quench was my main criteria. The lower heat & oil quenching of simple carbons are certainly more forgiving. Although I can argue it’s still giving it the ideal conditions by grinding after.

norseman

Active Member

I have never worked with Damascus and thought it was a reasonable cost to give it a try. I am gathering the material I need to heat treat. I picked up a Johnson forge at a school auction a number of years ago and it has set in my shed. I have it out and converted to propane. I ordered a Pyrometer so I could keep and eye on the temp. I have a gallon of Vet Mineral oil for quenching.

Thanks for all your help.

Thanks for all your help.

tkroenlein

Well-Known Member

How thick is the unground blade?

tkroenlein

Well-Known Member

Personally, I would normalize and do my grain refinement cycles at full thickness. Then I'd clean it up, and go to 50% on the bevels and austenitize. You don't want it too close to final dimension or you could have trouble getting rid of the decarb, which will show up when you etch it.

Do you know how the mineral oil compares to other common quenchants?

Do you know how the mineral oil compares to other common quenchants?

I can't say I know to much about quenching oils. I understand what normalizing is but not the grain refinement cycles

Grain refinement is a series of ever lower temp heatings and cool downs thus reducing grain size.

Read up on Kevin Cashen’s grain refinement recipe. His is the best I’ve read about. Or PM him. He’s a member here.

Or... Just read this.http://www.cashenblades.com/steel/1095.html

tkroenlein

Well-Known Member

If you're treating it as 1095 (is that what it is advertised as?), you will likely have some difficulty holding the correct temperature for an adequate amount of time for 1095. Setting up your forge with a muffle will help considerably.

If you're treating it as 1095 (is that what it is advertised as?), you will likely have some difficulty holding the correct temperature for an adequate amount of time for 1095. Setting up your forge with a muffle will help considerably.

It’s pattern welded, 1095/15N20. But as we all know, that means the edge is 1095.

This is the main reason I don’t like pattern welded steel. It’s not a homogeneous body. The long standing myth that this fake “Damascus” is somehow STRONGER, because the main steel is welded with a weaker steel(15N20). If anyone doesn’t know, go look at 15N20. I wouldn’t use it for ANY knife! So it doesn’t “magically” make the 1095 or 1080, 1084, BETTER! In fact, I believe it subsequently handicaps.

Again, pattern steel has a place because it makes functional knives that are nice to look at(if a person is into that look). But anyone thinking it’s some kind of “super steel”....or that it makes high performance knives, is fooling themselves.

bladegrinder

Well-Known Member

We all have opinions.

tkroenlein

Well-Known Member

Opinions are one thing, misinformation is another.

1) Proper forge welding does, in fact, create a homogenous blade.

2) The edge of the blade will consist of whatever steel crosses the edge of the blade, in this case, clearly two or more types that will impose the properties of both on the edge.

3) 15N20 is a nickel bearing high carbon steel, on par with similar alloys in strength, and demonstrably tougher than the higher carbide volume 1095.

My post that was quoted was about using a muffle. This post is to make sure the OP has good information to work with. I won't argue on the internet, and I will specifically not argue about steel on KD.

1) Proper forge welding does, in fact, create a homogenous blade.

2) The edge of the blade will consist of whatever steel crosses the edge of the blade, in this case, clearly two or more types that will impose the properties of both on the edge.

3) 15N20 is a nickel bearing high carbon steel, on par with similar alloys in strength, and demonstrably tougher than the higher carbide volume 1095.

My post that was quoted was about using a muffle. This post is to make sure the OP has good information to work with. I won't argue on the internet, and I will specifically not argue about steel on KD.

Chris Railey

Well-Known Member

I am pleased with my profile, going with brass bolsters and wood handle with brass pins. Is it better to Grind the blade before hardening?

Thanks Vern

You have been given some good advice by others but I will tell you what I do just so you know there is more than one way. With 1/8" steel I grind my primary bevel in the neighborhood of 10 degrees each side down to the thickness of about a dime. Then I go to heat treat. After, I grind the rest. Anything under 1/8' I do all grinding after heat treat and I generally plate quench these thinner blades. Anything over 1/8" I grind primary bevels as above then I will grind halfway to the spine in the neighborhood of three degrees then go to heat treat. After, I finish my grinding. Find what gives you the best results and do that.

Also, how are you heat treating your 1095? If you have precise temperature control, like a HT oven I would get the parks and use it. If you are doing simple heat treat in a forge or with a torch I would use the mineral oil. Without the temperature control, in my opinion, I would spare myself the expense of the parks. Or better yet just get some 1080 or 1084 and use that with your mineral oil.

P.S. I like your profile too.

Last edited: