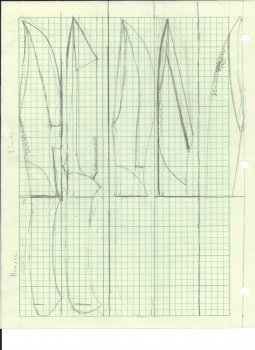

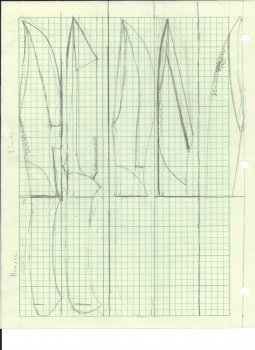

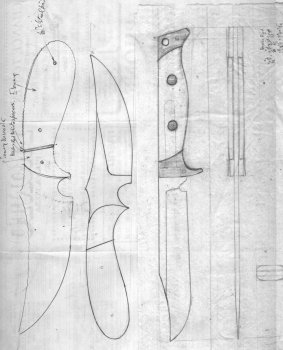

I know that at this stage your mind is abuzz with ideas, but after viewing the drawings, I think you're setting yourself up for failure with all the compound grinds, false edges and "saw teeth". Personally I dislike the profiles of the images because they all are "broke back". But that's just me. I would encourage simple designs with single grinds of your choice......and try to make those grinds and finishes the best you can. The skills required for a knifemaker are learned skills that very few come by naturally....meaning they require time and repetition. Concentrate on simple designs, and learn the elements that make a great knife..... beyond profile design, think about how and why a knife cuts well (grind gemoetry, edge geometry, etc) and learn how to incorporate those things into what you build. As your skills and confidence increase, add small elements a little at a time, otherwise you're desires will overshadow your skills, and you will get frustrated beyond belief. I think it's important for newer makers to have early successes, which means understanding what you're capable of doing, and only pushing yourself in small increments.