Smallshop

KNIFE MAKER

So, I've been sketching logos for a couple months. I couldn't decide whether to etch, or scratch engrave, pantograph/machine, or stamp. I finally realized after looking at a LOT of knife logos that:

1)I didn't want to tackle the learning curve of etching. And I've seen enough problematic things with some of the guys attempts here to think it's a breeze. I'd like to just focus on blade making and heat treating for a while.

2)Scratching with a diamond requires the same pantograph or machining skills. I don't care for the lower visibility.

3) Stamping really didn't make sense to me as I feel it's more appropriate on a forged blade. On a stock removal blade it doesn't make sense to me to heat a blade just to stamp it. I don't plan on forging for a long time.

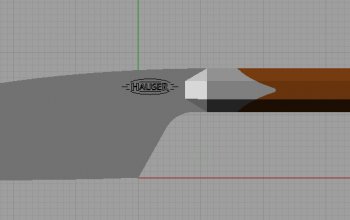

4) I decided that machining with a 1/32 carbide ball end mill would probably create a nice Logo. So I finished my design and then simulated in a CAM program to see what it looked like engraved. The simulation is set at pretty low resolution but you can get any idea. I went with a ball end mill as I did not want to introduce any stress areas that a square endmill might cause. In toolmaking an inside square corner is frowned upon on something you're going to heat treat.

So here it is greatly magnified. the actual size is .56 tall and .43 wide. The HK stand for Hauser Knives. I went with that over my name or initials. I have two boys that want to learn this.... so they can take over if I get tired/croak/do something new without having to change Logos.

Let me know what you guys think. Concerns, critiques, questions, etc appreciated.

Thanks,

Ted

1)I didn't want to tackle the learning curve of etching. And I've seen enough problematic things with some of the guys attempts here to think it's a breeze. I'd like to just focus on blade making and heat treating for a while.

2)Scratching with a diamond requires the same pantograph or machining skills. I don't care for the lower visibility.

3) Stamping really didn't make sense to me as I feel it's more appropriate on a forged blade. On a stock removal blade it doesn't make sense to me to heat a blade just to stamp it. I don't plan on forging for a long time.

4) I decided that machining with a 1/32 carbide ball end mill would probably create a nice Logo. So I finished my design and then simulated in a CAM program to see what it looked like engraved. The simulation is set at pretty low resolution but you can get any idea. I went with a ball end mill as I did not want to introduce any stress areas that a square endmill might cause. In toolmaking an inside square corner is frowned upon on something you're going to heat treat.

So here it is greatly magnified. the actual size is .56 tall and .43 wide. The HK stand for Hauser Knives. I went with that over my name or initials. I have two boys that want to learn this.... so they can take over if I get tired/croak/do something new without having to change Logos.

Let me know what you guys think. Concerns, critiques, questions, etc appreciated.

Thanks,

Ted