You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New forge

- Thread starter opaul

- Start date

Sean Jones

Well-Known Member

Very nice! Who makes that one?

Chris Railey

Well-Known Member

That looks like a Chili forge. Very nice brother.

opaul

Well-Known Member

It’s the one burner Tabasco from Chili Forge. Thanks. Can’t wait to get it set up.Very nice! Who makes that one?

CDHumiston

Well-Known Member

That is one sweet looking forge!

opaul

Well-Known Member

I have to say it is an incredibly made and attention to detail is outstanding. I got an extra floor to use when I attempt forge welding. Notice I said attempt- I’m about 50-50 right now with success. I’m hoping to improve that though. I took a local forge welding class and picked up some good advise. The class teaches using kerosene for the first flux clean and then borax.That is one sweet looking forge!

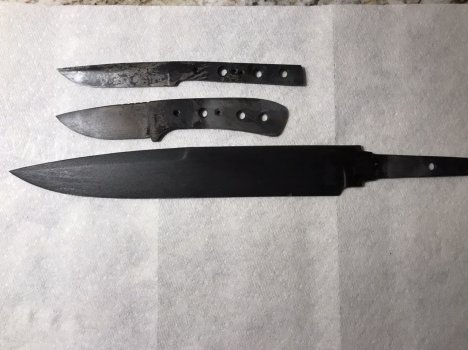

The billet wasn’t all that great but I think I can get a small bird and trout out of it. Top blade in photo.

Chris Railey

Well-Known Member

I use regular old 20 Mule team borax in a mustard squirter for flux. When I have kerosene around I have used it as a first flux so to speak. It works. The forge is great man I am happy for you.

opaul

Well-Known Member

Now if I can just get that Coal Ironworks press - I’ll be in business.I use regular old 20 Mule team borax in a mustard squirter for flux. When I have kerosene around I have used it as a first flux so to speak. It works. The forge is great man I am happy for you.

Yes - 20 team borax is what I use. Get it from Target.

opaul

Well-Known Member

I’ll try that. Couple questionsYou can ditch the Flux and kerosene altogether and just dry weld. I've had zero issues with weld flaws.

If you use a gas forge what PSI do you normally run?

How do you prep and assemble your steel.

J. Doyle

Dealer - Purveyor

My forge runs 25-30 psi for forge welding.I’ll try that. Couple questions

If you use a gas forge what PSI do you normally run?

How do you prep and assemble your steel.

Me and my buddy did an interesting experiment:

We layered up two identical billets. One we ground every piece clean and one we grabbed pieces right out of the box and did absolutely nothing to them. They both welded up perfectly. The only noticeable difference was the little black lines/inclusions on the edges of the non-prepped billet went a little deeper into the edges and took a bit more grinding to get rid of them. But neither had any weld flaws.

Me personally......I usually only grind the burr from the shear on the 15n20 off so everything stacks tight. I don't grind or do anything to the 1084. No cleaning with acetone or wiping with anything. The only thing I would address is if a saw a big rust spot. I'd grind any piece that was rusty. But mill scale I don't worry about at all.

I try to make sure my two outside layers are always as thick as possible.

A good grinder finish on the restacked pieces is fine after one weld. Personally, after the second weld, I surface grind all my restacks.

I am of the opinion that dry welding gives you cleaner, better and stronger welds than Flux welds.

Don't get me wrong ......fluxed welds can be perfectly fine, good and strong, but there is increased hassle and mess at best and potential for flaws at worst.

Chris Railey

Well-Known Member

John what do you mean by dry weld?dry weld

J. Doyle

Dealer - Purveyor

No Flux, no kerosene.....nothing. just stacked dry and welded.John what do you mean by dry weld?

Chris Railey

Well-Known Member

Welded all the way around or just tacked so it stays together?

J. Doyle

Dealer - Purveyor

Just tacked on the ends. I've never welded/closed up seams all around. I absolutely hate wasting time grinding out weld. So I don't put weld in the first place anywhere I have to grind it out.Welded all the way around or just tacked so it stays together?

opaul

Well-Known Member

I had read that. That’s why I’m using sacrificial floors. But after reading your method I’m going to dry dry stack welding.Flux will absolutely destroy those floor plates on that chili forge and it will happen quickly. I know from first hand experience.

Chris Railey

Well-Known Member

Who knew John had some rebel in him? Going against all established knowledge of cleaning, fluxing and major prep work for a forge weld. I am impressed! I have already forgone the whole cleaning with acetone stuff and I only tack weld the ends of my billets now because they are easy to cut off but you have gone further. What about when you cut and restack? What kind of clean up do you do there?

Last edited:

opaul

Well-Known Member

I believe he said just a grinder finish.Who knew John had some rebel in him? Going against all established knowledge of cleaning, fluxing and major prep work for a forge weld. I am impressed! I have already forgone the whole cleaning with acetone stuff and I only tack weld the ends of my billets now because they are easy to cut off but you have gone further. What about when you cut and restack? What kind of clean up do you do there?

Chris- what PSI are you using for those billets. You have a Mathew’s forge if I’m not mistaken.