RangerMadeKnives

KNIFE MAKER

Since I'm new here, I wasn't really sure where to put this but, I felt like this was the best place. This is really not going to be a WIP; just some progress pics and some photos of the finished knife when I get there.

I've been carrying around my third folder in my pocket for about three months now. It is a tactical liner lock flipper with textured G10 scales and a tanto grind blade. It has been taken apart, reworked, tweaked and beat on until I am finally satisfied with what I've got. I've made a couple other folders since but, now I think it is time to make another of this design.

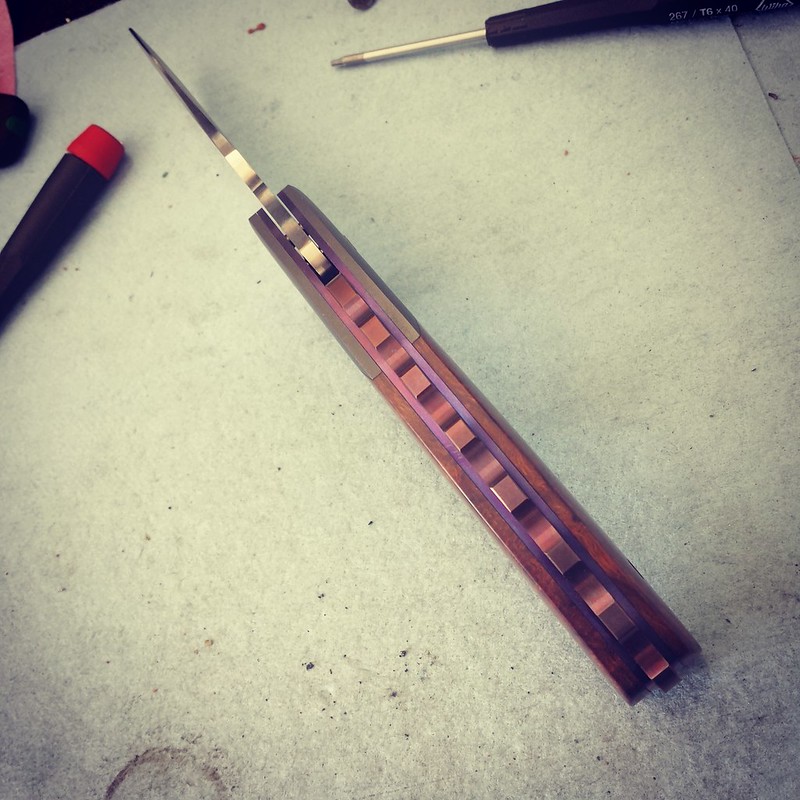

This knife has a blade of AEB-L, Titanium liners and backspacer, Zirconium bolsters and Desert Ironwood scales. This first pic was from the other day when I started on it.

Untitled by Bob, on Flickr

Untitled by Bob, on Flickr

Today after contouring the bolsters and scales.

Untitled by Bob, on Flickr

Untitled by Bob, on Flickr

One side with the bolsters bead blasted and heat colored.

Untitled by Bob, on Flickr

Untitled by Bob, on Flickr

I've got the blade wrapped and ready for HT in the morning. With any luck I can at least get the blade finished tomorrow.

Bob

I've been carrying around my third folder in my pocket for about three months now. It is a tactical liner lock flipper with textured G10 scales and a tanto grind blade. It has been taken apart, reworked, tweaked and beat on until I am finally satisfied with what I've got. I've made a couple other folders since but, now I think it is time to make another of this design.

This knife has a blade of AEB-L, Titanium liners and backspacer, Zirconium bolsters and Desert Ironwood scales. This first pic was from the other day when I started on it.

Untitled by Bob, on Flickr

Untitled by Bob, on FlickrToday after contouring the bolsters and scales.

Untitled by Bob, on Flickr

Untitled by Bob, on FlickrOne side with the bolsters bead blasted and heat colored.

Untitled by Bob, on Flickr

Untitled by Bob, on FlickrI've got the blade wrapped and ready for HT in the morning. With any luck I can at least get the blade finished tomorrow.

Bob