MTBob

Well-Known Member

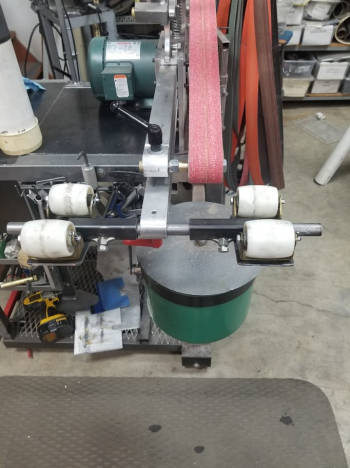

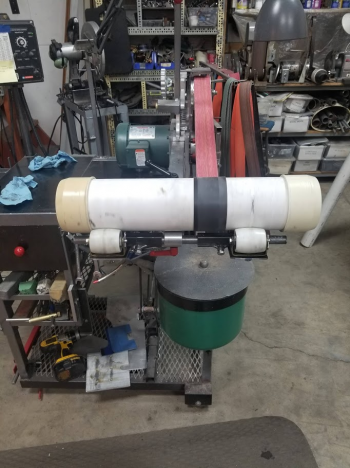

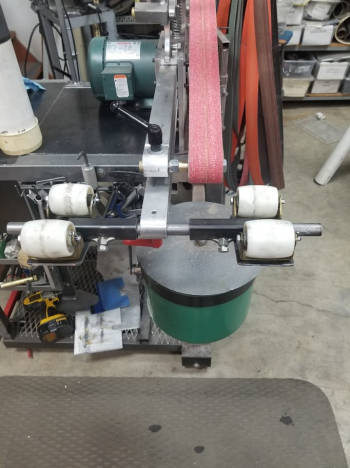

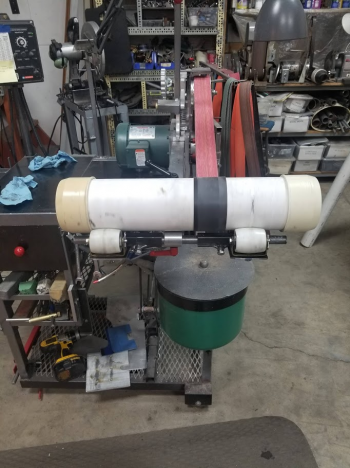

I've been using "Tumblers Tumbler" for stone washing small knives, but it's too short for larger knives. So, I decided to use the 2x72 grinder to roll a 4" PVC pipe. A design concept similar to others I've seen on the InterWeb.

I set the pipe so it just touches the 2" contact wheel, using a 36 grit belt. Adding rubber to the pipe gives a bit more grip.

I'm thinking a set of 4 swivel casters might have worked better. But, so far after tumbling several blades, this seems to work OK.

Also, I think a 6" pipe might work better than this 4" pipe. A 6" pipe will turn slower and allow for better tumbling action.

I set the pipe so it just touches the 2" contact wheel, using a 36 grit belt. Adding rubber to the pipe gives a bit more grip.

I'm thinking a set of 4 swivel casters might have worked better. But, so far after tumbling several blades, this seems to work OK.

Also, I think a 6" pipe might work better than this 4" pipe. A 6" pipe will turn slower and allow for better tumbling action.