Guindesigns

Well-Known Member

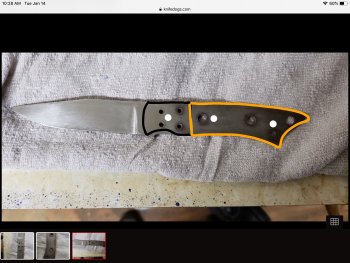

So I was asked to fix and finish this knife by a man whoms knifemaker friend pasted away before he could finish. Only problem is his friend had more experience than me. So I'm confused on how he planned to put a gaurd on this knife. The end is wider than the area at which the guard goes and there is no pin holes for me to slide a gaurd on and pin it. I see the holes for the bolsters but nothing for the guard. Any thoughts.?? Or suggestions?? I'd really like to finish this how it was originally designed but if I had to will just do away with the guard all together but I'd rather not.