Can someone give me a real quick how to?

Uh....unless you're making a straight razor.....just don't.

Do you grind your edge down first like a flat grind

You grind edge down? Wow! I've only seen one other person ever do that successfully. Every grind I do is edge up. For a hollow grind, that is doubly important to me....because that grind SHOULD intersect in/at the cutting edge. When a true hollow grind is done, it should already be sharp, and at the very most, a very light pass or two on a super fine grit belt or stone.

The first couple of passes are the most important ones, because they "set" where the hollow will be centered/begin. From that point as you grind deeper, the edges of the hollow should go towards the spine and the edge equally. The diameter of the wheel you use for hollow grinding dictates how small or large the hollow can/will be, for the thickness of the blade/stock. Very often the first couple of attempts results in grinding through the middle/center line of the blade.... that is IF you are going for a true hollow grind. Doing what I called the "bastardized" version is super easy, because you don't care about how thick the edge is, you just try to match the hollows distance from the spine on each side, and call it good. Then you grind the crap outta a huge blade flat until you get a huge chisel edge, and call it good. Is it showing that I don't like that grind?

Just my opinion, but hollow grinds are for very specific knives/uses. Straight razor and/or SOME culinary blades. To explain, a true hollow grind, is two arcs, one on each side of a blade, that start at the spine, and intersect AT the edge. This makes for an extremely sharp, but also a very delicate blade/edge.

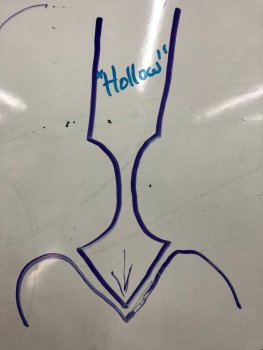

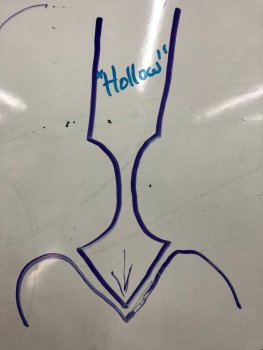

What most call a "hollow grind" these days is just a bastardized version that was made popular way back when Buck knives did it on their 110 folder for all the wrong reasons. It was done to increase strength at the edge of an overly hard blade, but at the same time it built/builds in a huge amount of cutting resistance, due to the huge, obtuse edge bevels required to create an edge. What's funny, is that if you search for "knife blade grinds" or "hollow grind", you will not find what most do/call a "hollow grind". What I see the vast majority of the time is something like this, and closely resemble what you see to this day on Buck's 110 folders:

Sorry for my crude rendition. I looked for my images, but couldn't find them, so I scribbled this one on my white board and took a pic.