PetrifiedWood

Well-Known Member

I don't have my first attempt at making a knife, but I can tell you about it. It was a piece of steel bar stock, the kind you find in the rack at a hardware store for fabricating things with a welder. Definitely not high carbon steel of any kind. One of my friends at the time had a party at his house (parents were out of town0 and we somehow ended up in the garage. After cutting out the profile of a big 10" blade bowie/Rambo looking thing with a hack saw, I used his dad's 4X36 belt sander to put what I would later learn is called a scandi grind on it. Then I made a bunch of notches in the spine using a cut-off wheel to make a saw back. It got the electrical tape handle treatment, as mentioned above. The rest of the guys at the party loved it. We didn't know a thing about heat treatment. But it looked as good as the junk they sold at the flea markets so it was a lot of fun.

Anyhow, fast forward a couple of decades. Now we have the internet and I decided I wanted to make knives so I did some research, bought a few books and read up as much as I could to give myself a shot at making a decent knife right from the start.

This was the very first knife I ever made from start to finish out of real steel, anyway. It's A2, and I probably botched the HT. I gave it as a gift to my FIL, and he hasn't complained about the edge holding so either it's better than I thought, or he just doesn't use it. You can't see the uneven plunge in the picture. but the knife was supposed to be a flat grind. I tried the freehand thing and it didn't work out for me. not wanting to waste the steel, I did my best to salvage it be doing a convex grind instead. The handle is dymondwood. Also another of those beginner cliches I suppose. I still like the stuff. Anyhow the only reason this knife doesn't look worse than it does is because of site like this where people freely share their knowledge and experience. It enabled me to sidestep some beginner mistakes, but there simply is no substitute for actual shop time. There are some things you can only learn by doing.

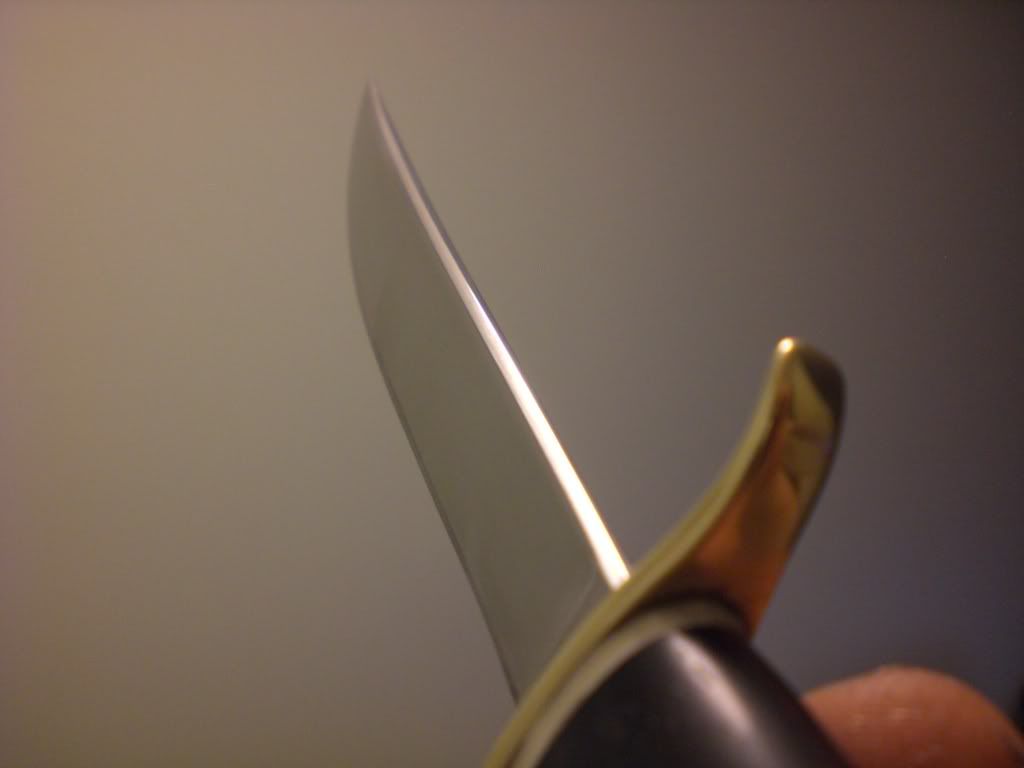

And here's my most recent knife. This is probably my 30th or so. Sadly, I haven't made a knife in months. Wife and I bought a new house and I haven't moved my tools yet from the old shop.

I still have a looooong way to go and a lot to learn. Hopefully I can get my shop moved and set up and get back to making knives before I forget what I'm doing and have to start over! :34:

Anyhow, fast forward a couple of decades. Now we have the internet and I decided I wanted to make knives so I did some research, bought a few books and read up as much as I could to give myself a shot at making a decent knife right from the start.

This was the very first knife I ever made from start to finish out of real steel, anyway. It's A2, and I probably botched the HT. I gave it as a gift to my FIL, and he hasn't complained about the edge holding so either it's better than I thought, or he just doesn't use it. You can't see the uneven plunge in the picture. but the knife was supposed to be a flat grind. I tried the freehand thing and it didn't work out for me. not wanting to waste the steel, I did my best to salvage it be doing a convex grind instead. The handle is dymondwood. Also another of those beginner cliches I suppose. I still like the stuff. Anyhow the only reason this knife doesn't look worse than it does is because of site like this where people freely share their knowledge and experience. It enabled me to sidestep some beginner mistakes, but there simply is no substitute for actual shop time. There are some things you can only learn by doing.

And here's my most recent knife. This is probably my 30th or so. Sadly, I haven't made a knife in months. Wife and I bought a new house and I haven't moved my tools yet from the old shop.

I still have a looooong way to go and a lot to learn. Hopefully I can get my shop moved and set up and get back to making knives before I forget what I'm doing and have to start over! :34: