You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Milling machine help

- Thread starter Gliden07

- Start date

John Wilson

Well-Known Member

me too

John Wilson

Well-Known Member

Here you go.

I have 3 axis DRO on this mini mill. These iGaging DROs are basically long digital calipers. The scale would be the handle of the caliper and the sensor is that same rectangular block that slides on the scale. Some of the iGaging DROs are exactly that: the sliding sensor actually has the digital display on the sensor, just like your digital caliper. This model has a wire that goes from the sensor to an external display.

The Z-axis is here on the column on the right side of the mill. The scale is fixed to the column. The sensor attaches to the head/quill with a bracket. As the head is raised or lowered it pushes the sensor along the scale. This axis os dead simple to install. Simply drill amd tap the column and head for the mounting screws.

I have 3 axis DRO on this mini mill. These iGaging DROs are basically long digital calipers. The scale would be the handle of the caliper and the sensor is that same rectangular block that slides on the scale. Some of the iGaging DROs are exactly that: the sliding sensor actually has the digital display on the sensor, just like your digital caliper. This model has a wire that goes from the sensor to an external display.

The Z-axis is here on the column on the right side of the mill. The scale is fixed to the column. The sensor attaches to the head/quill with a bracket. As the head is raised or lowered it pushes the sensor along the scale. This axis os dead simple to install. Simply drill amd tap the column and head for the mounting screws.

John Wilson

Well-Known Member

John Wilson

Well-Known Member

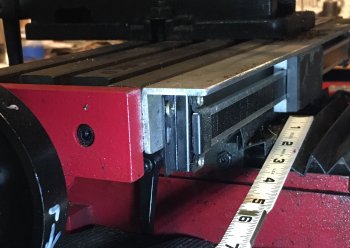

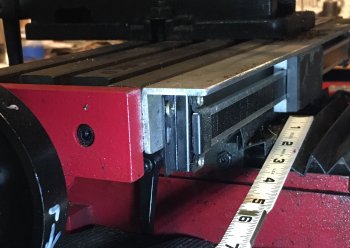

the X axis

This is on the back side of the cross slide. The cross slide doesn’t travel far enough in the Y axis to smash it into the column.

The slide bolts onto the back side of the hold down table. I sandwiched in a piece of aluminum angle to act as a drip guard.

The sensor is mounted via a bracket to the body of the mill. In this case the sensor never moves. The slide goes back and forth past the sensor as the cross slide travels along the X axis.

the bracket for the sensor goes down through a slot i cut in that ruffled chip bellows

This is on the back side of the cross slide. The cross slide doesn’t travel far enough in the Y axis to smash it into the column.

The slide bolts onto the back side of the hold down table. I sandwiched in a piece of aluminum angle to act as a drip guard.

The sensor is mounted via a bracket to the body of the mill. In this case the sensor never moves. The slide goes back and forth past the sensor as the cross slide travels along the X axis.

the bracket for the sensor goes down through a slot i cut in that ruffled chip bellows

Last edited:

John Wilson

Well-Known Member

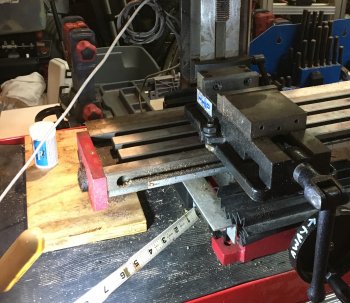

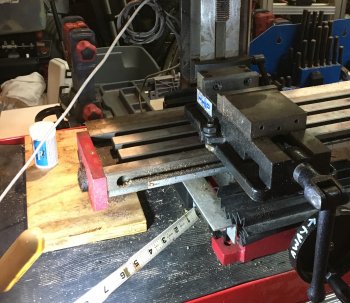

The Y-axis was the trickiest to mount. The reason for this was I wanted to use aluminum angle as a drip guard here, too.

What I did was to cut a long slot into the back side of the angle to allow the sensor bracket to pass through the slot. This allows the bracket/sensor to travel freely along the slot in the drip guard. The slide is mounted to the drip guard and does not move. Once I figured out the whole slot thing this was a piece of cake.

What I did was to cut a long slot into the back side of the angle to allow the sensor bracket to pass through the slot. This allows the bracket/sensor to travel freely along the slot in the drip guard. The slide is mounted to the drip guard and does not move. Once I figured out the whole slot thing this was a piece of cake.

Last edited:

John Wilson

Well-Known Member

Drew Riley

Well-Known Member

iGaging makes some really nice stuff, and it's hard to beat their prices, but I'd recommend taking a look at some of the Chinese DROs on eBay, or even AliExpress (if you dare). You can get a 2 or 3 axis kit with readout, scales, and even mounting hardware, for less than $100 per axis.

You'll get a lot more functions with those DROs, like bolt hole patterns, arc functions, dividing dimensions, etc...

Definitely worth the extra cost when you need that kind of thing.

You'll get a lot more functions with those DROs, like bolt hole patterns, arc functions, dividing dimensions, etc...

Definitely worth the extra cost when you need that kind of thing.

John Wilson

Well-Known Member

iGaging makes some really nice stuff, and it's hard to beat their prices, but I'd recommend taking a look at some of the Chinese DROs on eBay, or even AliExpress (if you dare). You can get a 2 or 3 axis kit with readout, scales, and even mounting hardware, for less than $100 per axis.

You'll get a lot more functions with those DROs, like bolt hole patterns, arc functions, dividing dimensions, etc...

Definitely worth the extra cost when you need that kind of thing.

Very true. If I had a knee mill without DRO that’s the way I’d go. I didn’t figure on ever doing that stuff on this little mill.

springer82

Well-Known Member

iGaging makes some really nice stuff, and it's hard to beat their prices, but I'd recommend taking a look at some of the Chinese DROs on eBay, or even AliExpress (if you dare). You can get a 2 or 3 axis kit with readout, scales, and even mounting hardware, for less than $100 per axis.

You'll get a lot more functions with those DROs, like bolt hole patterns, arc functions, dividing dimensions, etc...

Definitely worth the extra cost when you need that kind of thing.

Just wondering. As a knife maker what hole patterns would you make that you would need a readout? What would you use for XY 0.0?

Jason Volkert

Well-Known Member

I have been looking into a table top mill for a while now. I recently found this website in a machinist mag. Dropros.com. There mills look very similar to precision Mathews with better options and better price IMHO. Check them out to if you want

Drew Riley

Well-Known Member

Just wondering. As a knife maker what hole patterns would you make that you would need a readout? What would you use for XY 0.0?

If you're just using it to make knives, you probably won't be laying too many bolt hole patterns for knives. If you build your own grinders, you might find it useful for laying out holes to mount a c-faced motor I suppose (assuming what you're drilling will fit on the mill of course). The bolt hole layout function is only one of several additional functions on your average DRO.

Being able to find the center between edges is a really useful feature. Just use an edge finder to find your first edge, zero the DRO, traverse to the opposite edge, then use the "1/2" function on which ever axis you're traversing across. Traverse back to zero, and that's the dead center of whatever piece you're drilling. Or you can divide into 3rds, quarters, etc...

Now, just using a calculator with the iGaging DRO would do the exact same thing. There are also programs online to layout bolt patters and such too.

It really just depends on how much you plan on doing with your mill (which is going to be somewhat limited based on its size), and how much convenience you're after. I suppose you don't absolutely NEED anything more than the iGaging, but it is an option.

Just a word on the iGaging DRO - I had one of those setups on the lathe. I replaced it with the system I linked to in post #16 and there is no comparison between the two. AND, by the time you buy 2 or 3 of the iGaging units you've paid for a "real" DRO like I linked to. The iGaging DRO is better than nothing, but for the same price (or less) I'll take the units I linked to.

Last edited:

Drew Riley

Well-Known Member

One other thing to consider: The iGaging DRO does require a battery for each axis if I'm not mistaken. A standard DRO will how a power cord. Not sure how bad the battery consumption on the DRO is, but it does add up eventually.

John Wilson

Well-Known Member

One other thing to consider: The iGaging DRO does require a battery for each axis if I'm not mistaken. A standard DRO will how a power cord. Not sure how bad the battery consumption on the DRO is, but it does add up eventually.

That’s a good point. Each axis display is stand-alone and has its own battery. they take the typical CR2032 coin battery or whatever it is. It’s not a big deal but it would be better to have a power supply.

If I was to do it all again I think I’d use the unit Ken linked to. On a mini mill the iGaging solution works fine because you use a mini mill like an etch-a-sketch. But on a more capable machine I’d want a more capable DRO.

Motor City Mike

Well-Known Member

One other thing to consider: The iGaging DRO does require a battery for each axis if I'm not mistaken. A standard DRO will how a power cord. Not sure how bad the battery consumption on the DRO is, but it does add up eventually.

And they don't have an auto off. I leave mine on by mistake at least 50% of the time. Good thing I have a large supply of CR2032 batteries thanks to my wife's "extreme couponing"

Last edited:

John Wilson

Well-Known Member

And they don't have a auto off. I leave mine on by mistake at least 50% of the time. Good thing I have a large supply of CR2032 batteries thanks to my wife's "extreme couponing"

yep. same here.