Gliden07

Well-Known Member

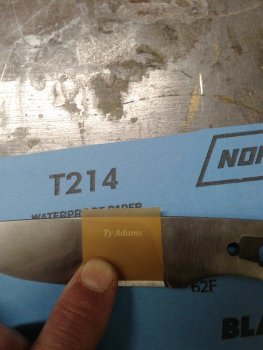

I did similar but I think getting the stencil straight is very hard for me. My thoughts behind all of this is that I think it would be easier for me to make a jig that would get it perfect (close lol) every time than taping the stencil right. That’s the real issue and motivation behind my post. @Ty Adams i should’ve explained myself better.

Huh? I thought that was he easy part? I take the clear one that Ernie sends drop it on to see where I might want it then just tape the stencil down to do the etch. I dont fuss to much with it. I think mine come out good.

Last edited: