LlamaHerder

Well-Known Member

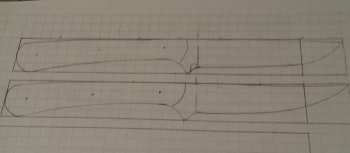

Hi all - starting a thread to post pictures of my knives as they're made. Am currently working on my second, which is progressing much more quickly and cleanly than my first. That's exciting!

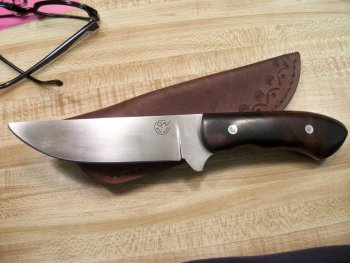

Also exciting to me - did a little testing today on my first knife. Should have done this before I permanently attached my handle material, but I was in a rush to finish a knife, I suppose. Mentally prepared to have a non-user first knife, I went to the garage...

Chopped through a 2x4, and it's still shaving sharp! Really surprised me, in a good way. I don't think any of the store bought knives I have would do this. They barely make it through field dressing one deer (granted, they're pretty cheap). Looking forward to cutting up other things to see how far I can push the edge on this knife. I'm a proud owner today. =) And I can trust my heat treating set up.

My second knife is going to a buddy, will post pics when it's finished, hopefully in a few days.

Also exciting to me - did a little testing today on my first knife. Should have done this before I permanently attached my handle material, but I was in a rush to finish a knife, I suppose. Mentally prepared to have a non-user first knife, I went to the garage...

Chopped through a 2x4, and it's still shaving sharp! Really surprised me, in a good way. I don't think any of the store bought knives I have would do this. They barely make it through field dressing one deer (granted, they're pretty cheap). Looking forward to cutting up other things to see how far I can push the edge on this knife. I'm a proud owner today. =) And I can trust my heat treating set up.

My second knife is going to a buddy, will post pics when it's finished, hopefully in a few days.