SHOKR

Well-Known Member

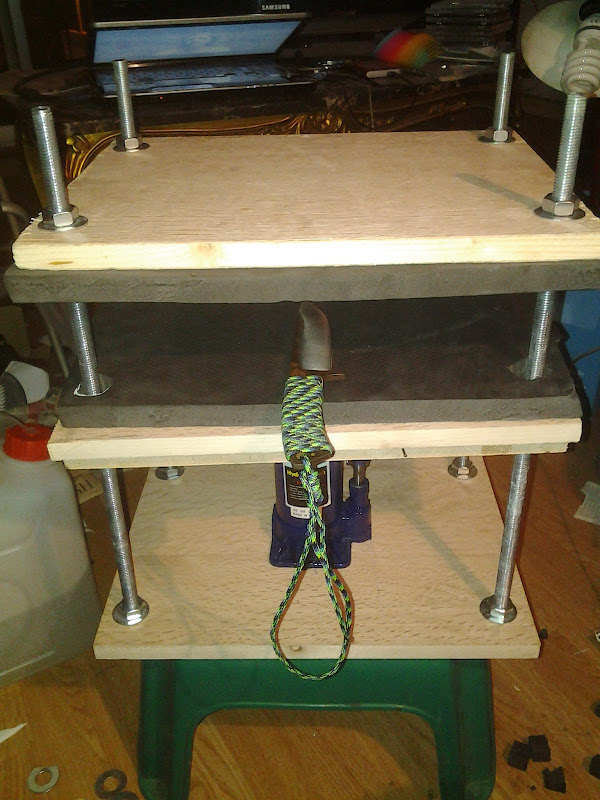

thats a press i'm working on

i saw a vid like it on youtube

real easy to build

that jack broke down (chinese, go figure) so will replace it with scissor one (this way i can control lifting and lowering)

i bought heat gun today, have a piece of kydex so will try as soon as i get the new Jack

i cut holes in the foam so it wont wiggle when pressing (i didnt want to glue because its temporary, pending success and how wood holds up)

if wood breaks i will replace it with metal

the guy in the video worked the jack with a drill instead of by hand, was neat!!

can do a WIP on that if anybody is interested, but you might find it online and its really simple anyway

i bought the foam locally, when i asked if it had any specs, the guy said and i quote ' thats the foam they make slipper soles from' its harder than neoprene, will see how it goes, if it doesnt work i'll buy online

if you have any tips for me though its all welcome!!