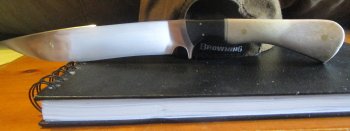

My third finished blade - about my tenth knife or so.

G-10 bolsters, with 1/16 stainless pins; nickel silver spacer (?); contoured caribou with 5/32 brass. Grey vulcanized fiber all around.

This is going to another bush-pastor friend of mine who does leatherwork. He said he wanted to make the sheath. Knife has something to be desired but I believe he'll be happy to make a sheath for it.

I hope you like it. Comments are welcome.

G-10 bolsters, with 1/16 stainless pins; nickel silver spacer (?); contoured caribou with 5/32 brass. Grey vulcanized fiber all around.

This is going to another bush-pastor friend of mine who does leatherwork. He said he wanted to make the sheath. Knife has something to be desired but I believe he'll be happy to make a sheath for it.

I hope you like it. Comments are welcome.

Attachments

Last edited: