Burl Source

Forum Owner & Moderator

First of all, I am not a fan of man made handle materials.

This piece of ??? came from the estate of Knife Maker Tedd Dowell.

I don't know if this is something worth cutting up or if it is junk.

I am leaning toward #2. But I figured I had better check before I toss it.

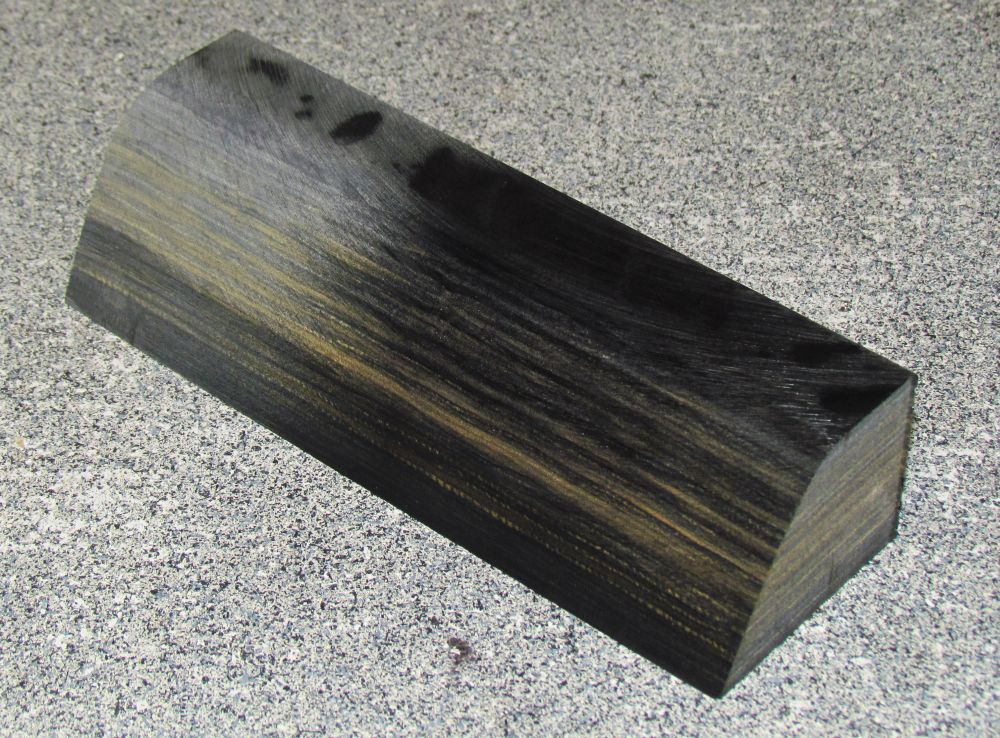

It is hard and heavy. Cuts and sands like a hard, hardwood.

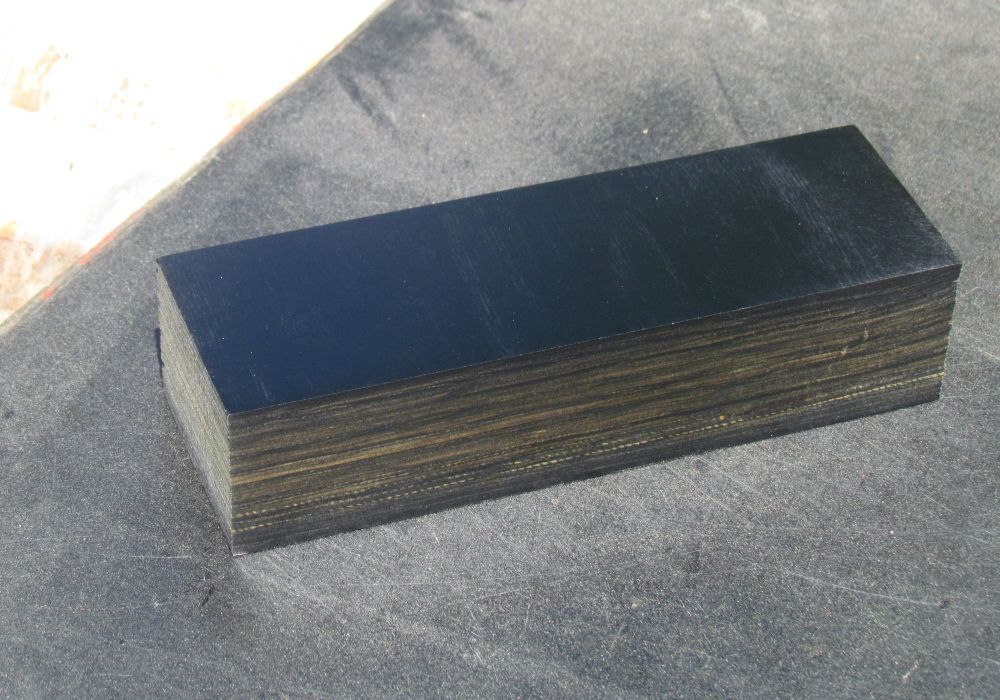

Looking at the edges it looks to be constructed of veneer slices with something like hard epoxy.

The layers are about as thick as a business card.

Any of you guys who were making knives in the 80s know what this is?

Block sanded to 120 grit.

This piece of ??? came from the estate of Knife Maker Tedd Dowell.

I don't know if this is something worth cutting up or if it is junk.

I am leaning toward #2. But I figured I had better check before I toss it.

It is hard and heavy. Cuts and sands like a hard, hardwood.

Looking at the edges it looks to be constructed of veneer slices with something like hard epoxy.

The layers are about as thick as a business card.

Any of you guys who were making knives in the 80s know what this is?

Block sanded to 120 grit.