Daniel Macina

Well-Known Member

Made you look didn’t I? Hahahaha!

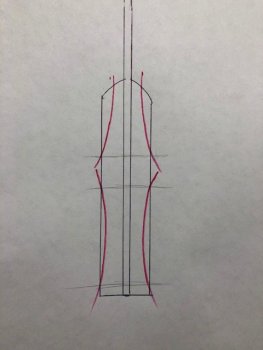

in all seriousness when shaping my handles I keep having trouble getting the butt to look right I like a nice swell similar to what is pictured here but cannot seem to get it consistently no matter how hard I try to keep my steps consistent from handle to handle. Was just wondering if anyone had any tips for a nice swell on the back end?

Thanks!

Thanks!

in all seriousness when shaping my handles I keep having trouble getting the butt to look right I like a nice swell similar to what is pictured here but cannot seem to get it consistently no matter how hard I try to keep my steps consistent from handle to handle. Was just wondering if anyone had any tips for a nice swell on the back end?

Thanks!

Thanks!