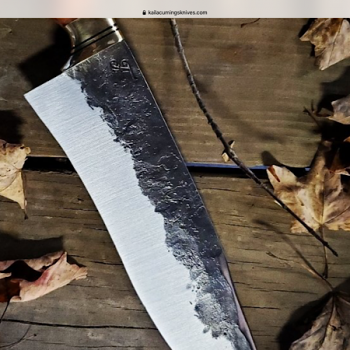

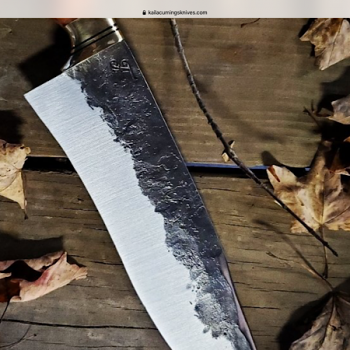

The line is curvy because it is a coarsely hammered blade. Think of it this way, the blade contains a lot of hammer marks, AKA low spots. When you grind bevels you are working with an uneven surface so the grind line is going to wander. If one does not wish to show hammer marks and achieve a straight grind line then they need to grind the surfaces flat before they grind bevels. I use a more traditional approach of using a flatter on all forged blades as a final step in my forging process. More info than you asked for but it gets the point across.

As for the color it can be achieved by applying oil while the blade is hot. Think of it like seasoning a cast iron skillet in your oven. Essentially the same process. I have done this many times on forged pieces but not knives. Normally I put them in a hot forge and rub canola oil on them while they are hot but for blades you have temper issues to worry about. If I were going to try it on the blade I would temper the blade first. Then start trying to darken the scale. If you temper at 400 then I would apply Canola Oil to the blade and bake it at 350 for a while. It may take a few applications to get it how you want but I would think it would work.