Randy Lucius

Well-Known Member

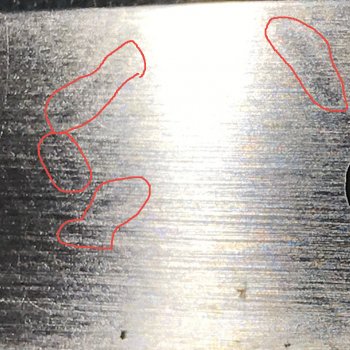

Working on a 440C blade. I can’t get a clean finish on it to save my life. It has a “smeared film” look to it. Almost like WD40 residue. Went up to 800 grit. Bad. Started over at 220 and back to 800. Still looks like crap. I’ve tried every finishing technique I know of. No luck. I’m ready to throw this #%€¥&@$ through the back shop wall. Any ideas?