Jason Wilder

Well-Known Member

I am in the process of finishing my first Gyuto (chef) and Pearing knife and did them both with a full flat grind with distil taper, but would like to try something different with my next kitchen blades

I would very much like to practice traditional Japanese grinds and need to be educated.

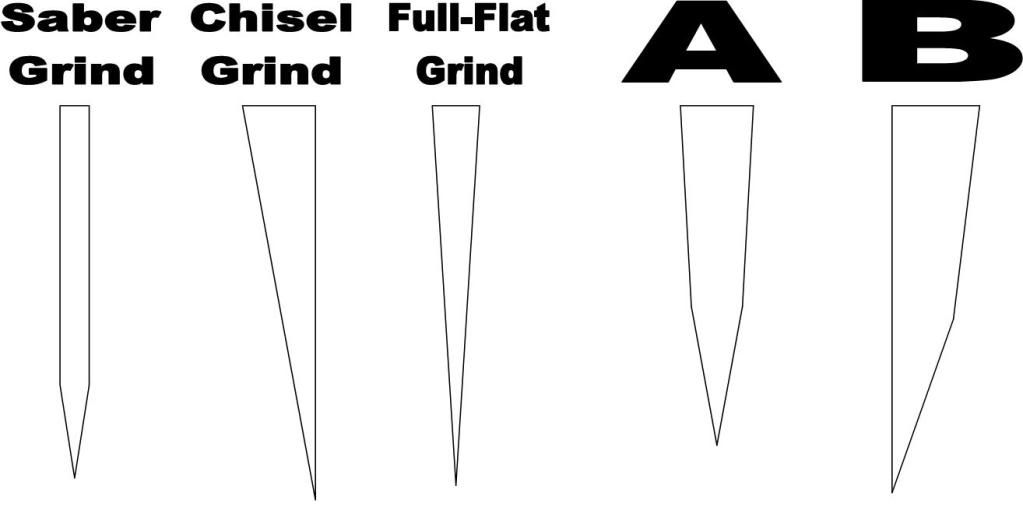

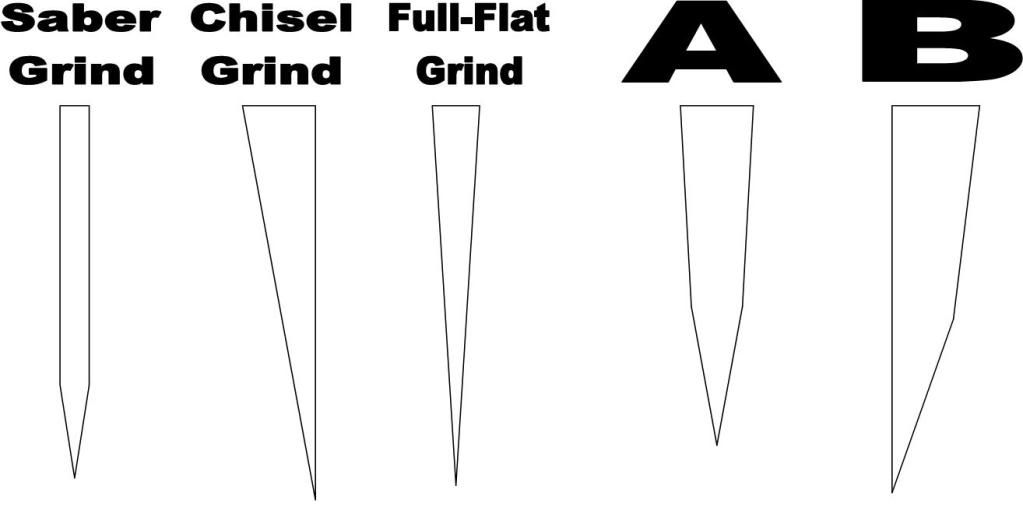

Here is a diagram I just drew and would like to know which to use for which knives

Unless I am mistaken I should have used the type of grind in figure A which begins with a full flat grind to about 1/3 of the thickness on either side, then a second bevel that begins about 1/3 from the edge. Does this make sense?

When would the grind in figure B be used?

My next project will be a Nikiri but am not sure which grind to use? I'd love to hear your thoughts, and please correct me if I mislabeled these grinds

Thanks,

Jason

I would very much like to practice traditional Japanese grinds and need to be educated.

Here is a diagram I just drew and would like to know which to use for which knives

Unless I am mistaken I should have used the type of grind in figure A which begins with a full flat grind to about 1/3 of the thickness on either side, then a second bevel that begins about 1/3 from the edge. Does this make sense?

When would the grind in figure B be used?

My next project will be a Nikiri but am not sure which grind to use? I'd love to hear your thoughts, and please correct me if I mislabeled these grinds

Thanks,

Jason