Sean Jones

Well-Known Member

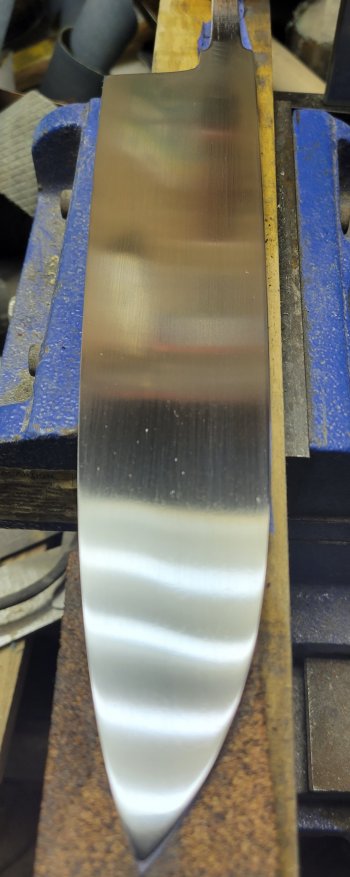

I have a 8 inch chef knife that I've done my first convex grind on. And it appears to have turned out OK before hand sanding. However I don't know how to hand sand a convex shape.

So how does one put a nice hand sand finish on a convex blade?

So how does one put a nice hand sand finish on a convex blade?