Redbaird

Well-Known Member

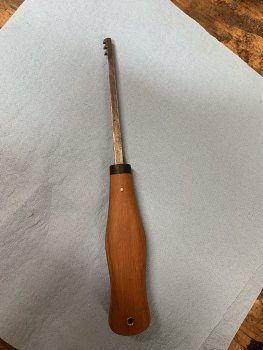

So... I really stink at holing a constant angle on a grind. I am sure I will get better with practice but patience is not a virtue I have. Yesterday I think I fixed my problem. I took a piece of oak and squared off 2 sides. Drilled 2 holes for adjustment bolts and counter drilled holes for the nuts. This allows me to adjust the angle of the jig. I attached 3 magnets to the side to hold the knife while grinding. After building and testing a few questions come to mind.

1. Does everyone who builds knives already have one of these?

2. Is there one of these out there that is 10 times better than mine?

3. What other cool home made items and gadgetry are out there that could save me time (and fingers)?

4. Is gadgetry even a word?

Let's see the backyard engineering!!!!!

![IMG_1185[1].JPG IMG_1185[1].JPG](https://knifedogs.com/data/attachments/50/50831-a08ea1fc15167792ac892f22728cbaaa.jpg)

![IMG_1186[1].JPG IMG_1186[1].JPG](https://knifedogs.com/data/attachments/50/50832-24b5250520a2d0c713c6a8f00ab2bb90.jpg)

![IMG_1188[1].JPG IMG_1188[1].JPG](https://knifedogs.com/data/attachments/50/50833-53d2448378ae3d52d9cd82681eebf626.jpg)

![IMG_1189[1].JPG IMG_1189[1].JPG](https://knifedogs.com/data/attachments/50/50834-4c48b3c8d5345481a53ad39e513a0404.jpg)

1. Does everyone who builds knives already have one of these?

2. Is there one of these out there that is 10 times better than mine?

3. What other cool home made items and gadgetry are out there that could save me time (and fingers)?

4. Is gadgetry even a word?

Let's see the backyard engineering!!!!!

![IMG_1185[1].JPG IMG_1185[1].JPG](https://knifedogs.com/data/attachments/50/50831-a08ea1fc15167792ac892f22728cbaaa.jpg)

![IMG_1186[1].JPG IMG_1186[1].JPG](https://knifedogs.com/data/attachments/50/50832-24b5250520a2d0c713c6a8f00ab2bb90.jpg)

![IMG_1188[1].JPG IMG_1188[1].JPG](https://knifedogs.com/data/attachments/50/50833-53d2448378ae3d52d9cd82681eebf626.jpg)

![IMG_1189[1].JPG IMG_1189[1].JPG](https://knifedogs.com/data/attachments/50/50834-4c48b3c8d5345481a53ad39e513a0404.jpg)