You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Grind Serrations with a Profile Grinder? What'da Ya Think?

- Thread starter MTBob

- Start date

Drew Riley

Well-Known Member

New tools are rarely a bad thing, and that one looks like doozy!

Whether or not I'd pick one up for serrations would depend mostly on the cost of entry, and even then, how often I'd try to use it for serrations would be questionable. I imagine you could do it just as well (and probably faster and more easily) by setting up a similar abrasive wheel on any horizontal shaft and cutting them in by hand. Another option, of course, is to use a 1/4" small wheel on your grinder, carbide burrs, or other similarly shaped abrasives.

Either way, that still looks like a cool machine.

Whether or not I'd pick one up for serrations would depend mostly on the cost of entry, and even then, how often I'd try to use it for serrations would be questionable. I imagine you could do it just as well (and probably faster and more easily) by setting up a similar abrasive wheel on any horizontal shaft and cutting them in by hand. Another option, of course, is to use a 1/4" small wheel on your grinder, carbide burrs, or other similarly shaped abrasives.

Either way, that still looks like a cool machine.

REK Knives

Well-Known Member

I'm not sure if that would work... I use a radius'd cbn wheel on a vfd bench grinder under coolant and grind them one at a time

Bruce McLeish

Well-Known Member

I really like that blade. Please show me the rest of that knife. Thanks.

MTBob

Well-Known Member

Totally agree. I'm skeptical whether this thing would "earn its keep" in my shop, it may be just too specialized (and take up too much real estate). Though I'm a sucker for mechanical things with knobs and motors, just too intriguing what it could be converted into. I'll take a look at it and see if the Price is Right.Whether or not I'd pick one up for serrations would depend mostly on the cost of entry, and even then, how often I'd try to use it for serrations would be questionable

I was unfamiliar with CBN wheels until your post, thanks. I'm now curious whether these CBN wheels are used much in typical knife grinding, mostly for hollow grinds. Could you share what your serration / grinder setup looks like?I use a radius'd cbn wheel on a vfd bench grinder under coolant

billyO

Well-Known Member

I'd be curious as to the price also. If you do end up picking it up, and find it works but that you don't make enough bread knives, I might be interested as I've been wanting to add bread knives to my repertoire, but haven't figured out an easy way to do good uniform serrations yet.see if the Price is Right.

MTBob

Well-Known Member

They are asking $300... haven't seen it yet... but I think my "why not price" is closer to$100, cause it'll take some McGiver'en to do what I want it to do. Not sure where it's built, so I'm curious about quality.I'd be curious as to the price also. If you do end up picking it up, and find it works but that you don't make enough bread knives, I might be interested as I've been wanting to add bread knives to my repertoire, but haven't figured out an easy way to do good uniform serrations yet.

REK Knives

Well-Known Member

It's a Hawk Deadlock, I didn't make it just did the serrationsI really like that blade. Please show me the rest of that knife. Thanks.

REK Knives

Well-Known Member

I run a 3 phase bench grinder w/ a VFD and mist cooling... the burr doesn't even turn brown so that keeps the edge quite cool. The CBN wheels cost about $300-400 each iirc. You can get different sizes too.Totally agree. I'm skeptical whether this thing would "earn its keep" in my shop, it may be just too specialized (and take up too much real estate). Though I'm a sucker for mechanical things with knobs and motors, just too intriguing what it could be converted into. I'll take a look at it and see if the Price is Right.

I was unfamiliar with CBN wheels until your post, thanks. I'm now curious whether these CBN wheels are used much in typical knife grinding, mostly for hollow grinds. Could you share what your serration / grinder setup looks like?

Last edited:

Drew Riley

Well-Known Member

That's a lot closer to the setup I'd imagine myself using. I am curious how you cut the thinner/smaller serrations. Is there a sharper wheel on the other side?I run a 3 phase bench grinder w/ a VFD and mist cooling... the burr doesn't even turn brown so that keeps the edge quite cool. The CBN wheels cost about $300-400 each iirc. You can get different sizes too.

Last edited:

Drew Riley

Well-Known Member

That price seems pretty reasonable. I'd probably be pretty tempted to pick it up just to play with, if anything.They are asking $300... haven't seen it yet... but I think my "why not price" is closer to$100, cause it'll take some McGiver'en to do what I want it to do. Not sure where it's built, so I'm curious about quality.

REK Knives

Well-Known Member

Yep its just a 1/4" width wheel shaped to more of a pointThat's a lot closer to the setup I'd imagine myself using. I am curious how you cut the thinner/smaller serrations. Is there a sharper wheel on the other side?

MTBob

Well-Known Member

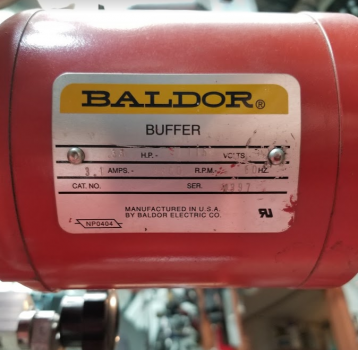

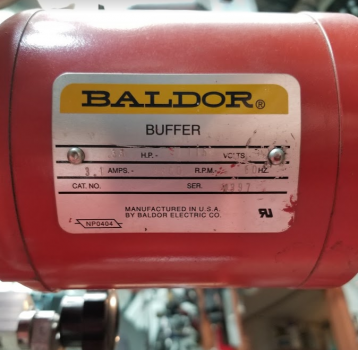

This profile grinder appears to be adaptable to a number of grinding applications. A Viel machine made in Canada with a Baldor motor.

Here's a little preliminary preview tour:

In this photo I'm holding the plastic template pattern plate (not ground yet) that attaches to the arm that rotates around the lower pivot slide. The pivot slide is controlled by the longitudinal thread that attaches to a half nut. Then on top of the pivot arm are four ball bearings that support a blade mounting trunnion fixture that rotates around an axis perpendicular to the grinding wheel. So, once attached to the fixture, a blade can travel left/right and in/out relative to the grinding wheel and be ground to the shape laid out on the plastic template.

In addition to these movements, the grinding wheel can move on an X/Y axis with this assembly. It would seem for simply cutting serrations, there actually may be too many adjustments.

How this all works to simply cut serrations in a knife is yet to be figured out... but the basic guts of a machine to do that seems to be in place.

This machine sports a USA made Baldor 1/3HP motor that turns at 3600 RPM. I'm concerned that with that speed it could easily burn a HT'd blade. I may cover the wheel and use a mister to see if that limits the potential heating issue. And, also of some concern, the wheels that came with the machine have a Max 3275 RPM rating...hum... I may try a Variac on the electrical input to see if that will work for speed reduction, without screwing up the horse power.

Here's a little preliminary preview tour:

In this photo I'm holding the plastic template pattern plate (not ground yet) that attaches to the arm that rotates around the lower pivot slide. The pivot slide is controlled by the longitudinal thread that attaches to a half nut. Then on top of the pivot arm are four ball bearings that support a blade mounting trunnion fixture that rotates around an axis perpendicular to the grinding wheel. So, once attached to the fixture, a blade can travel left/right and in/out relative to the grinding wheel and be ground to the shape laid out on the plastic template.

In addition to these movements, the grinding wheel can move on an X/Y axis with this assembly. It would seem for simply cutting serrations, there actually may be too many adjustments.

How this all works to simply cut serrations in a knife is yet to be figured out... but the basic guts of a machine to do that seems to be in place.

This machine sports a USA made Baldor 1/3HP motor that turns at 3600 RPM. I'm concerned that with that speed it could easily burn a HT'd blade. I may cover the wheel and use a mister to see if that limits the potential heating issue. And, also of some concern, the wheels that came with the machine have a Max 3275 RPM rating...hum... I may try a Variac on the electrical input to see if that will work for speed reduction, without screwing up the horse power.

bladegrinder

Well-Known Member

My spider senses tell me your onto something with this machine Bob.

it appears to have been made with quality in mind. now if it can be modded.

it appears to have been made with quality in mind. now if it can be modded.