Daniel Macina

Well-Known Member

Are they hiring?

Almost everything I do is stock removal so I’m good there.The thinner 01 would make great chef knives and Smaller Hunting and EDCs. But I would probably do them material removal forging blades under 3/16" is a pain!! I would also H/T prior to grinding to avoid warping. Good luck!!

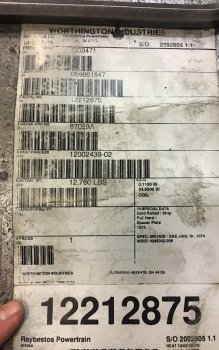

They may not be willing to give the MTR without him being the purchaser of the material. Your employer should have the MTR's, if you are making any sort of finished product they need traceability to protect themselves.You should be able to call Crawford Steel and get the specifics from them. I'd be pretty shocked if your purchasing and engineering folks didn't require certs for the material as well.

....Another supplier sells their 1095 with about 0.7%-0.8% manganese ......

Doug

I could be mistaken but wouldn't that MN content put that completely outside of spec for 1095?

Since it appears that the strip is not being annealed after cold rolling ("full hard"), you may need to do some additional processing in order to machine the steel (cut, drill, etc...). You can work around this a little bit with carbide drills, abrasive or plasma cutting, etc... but you may still want to normalize each blade at the very least before its final heat treat.