I know folks build in different manners, but when I build anything with a frame handle, I always have a mechanical method from the butt end. In my case, I often use a small clevis on the end of the tang, threaded 4-40, with a 4-40 screw through the rear of the frame. If that's a pin hole on the side of the handle in your drawing, those are a royal pain to try to get things aligned, and tight at the same time.

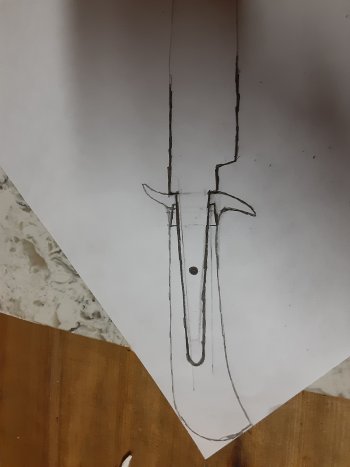

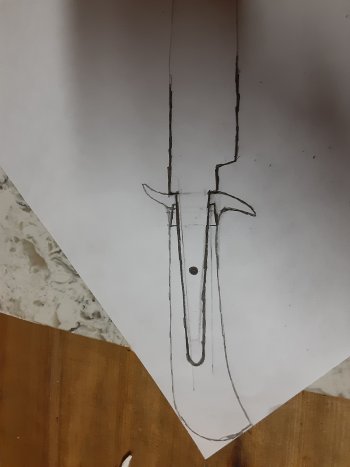

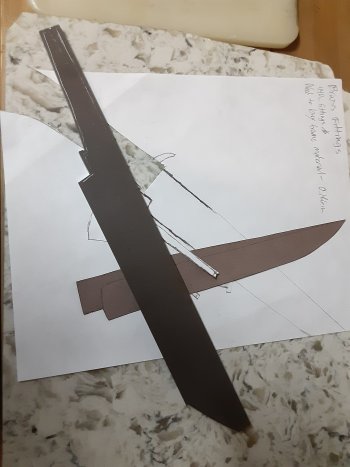

Here's the clevis I use...

https://www.amazon.com/Du-Bro-604-Solder-Kwik-Link-12-Pack/dp/B0006O8U0C/ref=sr_1_12?crid=209J113X937KL&dchild=1&keywords=4-40+clevis&qid=1611927009&sprefix=4-40+cle,aps,220&sr=8-12

I drill a 1/16" hole through the end of tang, spread the clevis and insert the pin through the hole (one side springs back into place), and you have enough "motion" to allow everything to be drawn up tight..... without pulling anything off, one way or another. I use these clevises for just about anything I build with a buttcap, or a "through tang" type of construction. I personally choose to glue everything up anyway.....but if you're neat and tidy, it makes for a great take-down type construction too. I just choose to glue, because I've had far too many clients wreck "take downs" in the past....everything from stripping threads, to scaring up fittings.....and then wanting me to repair their mistakes for free.

I also counterbore the hole through the back of the handle frame to fit the head of the 4-40 screw I use....or sometimes will even turn down the head if I choose. Some filework and/or coloring on the screw head adds a nice tough of detail.