Well let me start off by saying, Im just a blacksmith..We make mostly tools, Axes,Hawks and some knives..Dont really consider myself a bladesmith but can make a decent enough knife..This is one of the tutorials we are gonna post that may help someone.. I may not be the worlds best grinder but I know my way around a hammer and how to weld with one so here we go :biggrin:

----------------------------------------------------------------

..This is going to be a bearded, polled bag axe..Used mostly for hunt'n chore's..The body is 1045 and the cutting bit will be 1095fg..You'll notice in the pics everything is done by hand..I always liked doing it that way but to be honest we dont have a mill or a lathe or a power hammer so we dont have a choice anyway :sad: We'd use them if we did but we dont :noway:

To start: In the coal fire

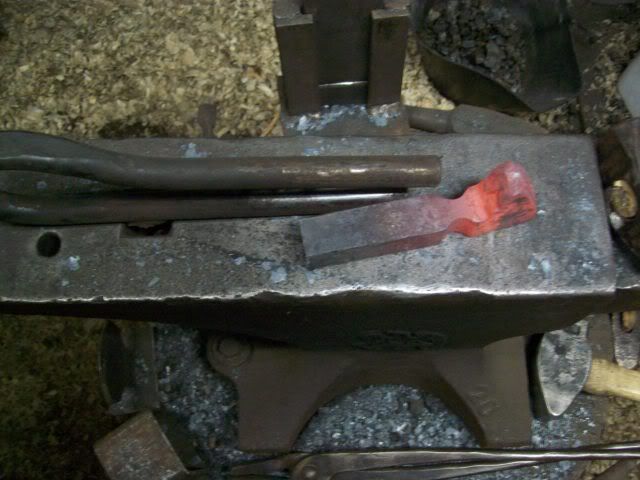

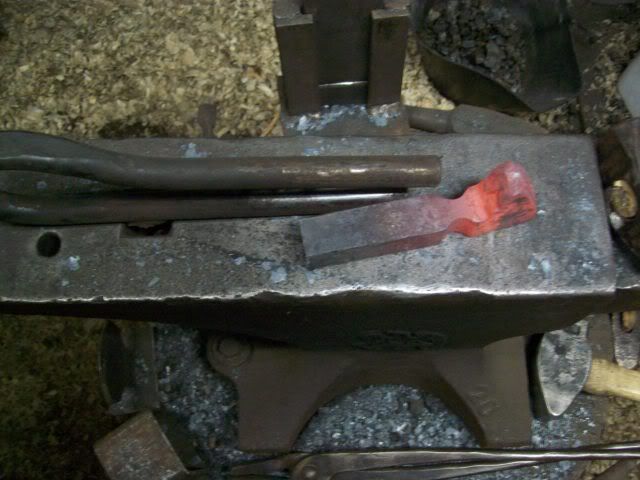

Here we forgot to take a pic of upsetting the end but we have upset it and forged a very rough blade shape.The reason we upset it is to have enough mass for a bearded head..Unless the blade close to 3x as wide as the width of the eye body its not bearded to me .Then we have it in a hold hardy tool so we can split the head to accept the wedge of 1095fg..

.Then we have it in a hold hardy tool so we can split the head to accept the wedge of 1095fg..

Here is the "blade" split with the cutting bit in it ready to weld up..

Here is the first welding pass..We do two-three passes..

Here we use a spring fuller to fuller the blade between where the eye will be and the rest of the blade..Just makes it easier to control the blade forging.

Here we have measured and marked both sides of the head after cooling with a cold chisel. This is where we will hot slit the eye..

Here we have started. Go thru BOTH sides and then you can meet in the middle..

After you have done a few bucket full of these it will meet perfectly in the middle like this

Here we have a flat drift thru the eye to forge the ears on. Again here we use a spring fuller..Later when we drift it to shape we will fuller some more on the eye drfit.

,

Here its starting to be forged out..

Over the horn to set the blade profile..

The blade pretty muchs set and ready to clean up..We will forge the edge bevels in after the cutout is done so we can leave a forge finish..The blade has to be clean and level to do the cutout right..

The head is cleaned up somewhat and the holes set for the cut out..In this case a deer track (buck of course) after this its all elbow grease and files..

After a long time and sore elbow heres the deer track..

Stamping the poll...

Well this is it..During heat treat we did forge the bevel and left a forge finish per request..It was edge hardened and tempered and the hammer poll was also heat treated like a regular hammer..

4 5/8" wide bearded cutting edge. Hair poppin sharp..

----------------------------------------------------------------

..This is going to be a bearded, polled bag axe..Used mostly for hunt'n chore's..The body is 1045 and the cutting bit will be 1095fg..You'll notice in the pics everything is done by hand..I always liked doing it that way but to be honest we dont have a mill or a lathe or a power hammer so we dont have a choice anyway :sad: We'd use them if we did but we dont :noway:

To start: In the coal fire

Here we forgot to take a pic of upsetting the end but we have upset it and forged a very rough blade shape.The reason we upset it is to have enough mass for a bearded head..Unless the blade close to 3x as wide as the width of the eye body its not bearded to me

Here is the "blade" split with the cutting bit in it ready to weld up..

Here is the first welding pass..We do two-three passes..

Here we use a spring fuller to fuller the blade between where the eye will be and the rest of the blade..Just makes it easier to control the blade forging.

Here we have measured and marked both sides of the head after cooling with a cold chisel. This is where we will hot slit the eye..

Here we have started. Go thru BOTH sides and then you can meet in the middle..

After you have done a few bucket full of these it will meet perfectly in the middle like this

Here we have a flat drift thru the eye to forge the ears on. Again here we use a spring fuller..Later when we drift it to shape we will fuller some more on the eye drfit.

,

Here its starting to be forged out..

Over the horn to set the blade profile..

The blade pretty muchs set and ready to clean up..We will forge the edge bevels in after the cutout is done so we can leave a forge finish..The blade has to be clean and level to do the cutout right..

The head is cleaned up somewhat and the holes set for the cut out..In this case a deer track (buck of course) after this its all elbow grease and files..

After a long time and sore elbow heres the deer track..

Stamping the poll...

Well this is it..During heat treat we did forge the bevel and left a forge finish per request..It was edge hardened and tempered and the hammer poll was also heat treated like a regular hammer..

4 5/8" wide bearded cutting edge. Hair poppin sharp..