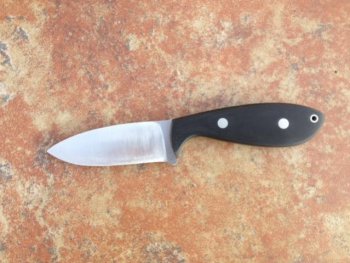

Well, I finally finished a blade. This is my first one, but I have been making numerous knives concurrently to practice each step. Of course, grinding the bevels is where I spent some time....

This knife is 7" OAL and made from 1/8" 1084 steel from Aldo. I heat treated and tempered the knife with Ernie Balch at his shop. It is full flat ground with a convex edge. The handle in black canvas micarta with red liners hand finished to 1200 grit. I think I am going to sand a couple spots a touch more.

The knife is meant to be an EDC and I am calling it the pinch. The gentleman who wanted it, wanted me make a design where the first finger and thumb felt very close to each other for control almost like your pinching the blade. The name stuck with me...

Special thanks to Darrin Sanders and Ernie Balch. Both of these people inspired me to try this hobby and lent me a tremendous amount of time to help me learn. I am grateful for their support!

Please forgive the iPhone pictures. That's all I had on hand...

Keith

This knife is 7" OAL and made from 1/8" 1084 steel from Aldo. I heat treated and tempered the knife with Ernie Balch at his shop. It is full flat ground with a convex edge. The handle in black canvas micarta with red liners hand finished to 1200 grit. I think I am going to sand a couple spots a touch more.

The knife is meant to be an EDC and I am calling it the pinch. The gentleman who wanted it, wanted me make a design where the first finger and thumb felt very close to each other for control almost like your pinching the blade. The name stuck with me...

Special thanks to Darrin Sanders and Ernie Balch. Both of these people inspired me to try this hobby and lent me a tremendous amount of time to help me learn. I am grateful for their support!

Please forgive the iPhone pictures. That's all I had on hand...

Keith