Chris Railey

Well-Known Member

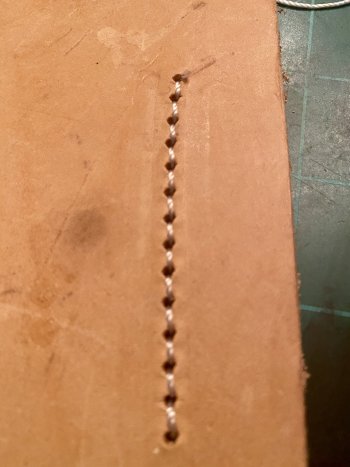

I literally received my machine yesterday. I got home form work about 1800 hours and ate dinner then started opening the machine at about 1920. The machine comes with five bobbins, a bobbin winder, a professional thread stand, a big fat spool of really good thread and some spare parts. The machine is heavy, I would guess right at 50 pounds. The body is mostly cast iron. From the time I opened the package to the time she was ready to sew was about 15-20 minutes. First thing you do, trust me, is to mount it to a stable surface. The base is small and it will tip forward easily until you secure it. I used two big spring clamps and my dinning room table. Next you mount the crank handle literally five minutes and one Allen wrench. Next, you thread the machine, maybe two minutes. The bobbin is already filled and the thread is already pulled up. Bam it's ready to sew. I sewed two pieces of scrap together and it worked perfectly. I then went searching for something else to sew and I found two sheaths that were ready to glue and sew. I had already marked the stitch holes with my stitching chisel but I decided to sew it any way. Sewed first sheath, sewed second sheath maybe three minutes of stitching each because I was going slow and thinking along the way. I would post pictures but because I already marked chisel holes the holes look extra big and are not representative of what the machine does. The stitches were tight and look very nice. I tried to pull the scrap pieces apart and no luck they were tight. I am super impressed with the machine. If I did not have to work this morning I could have made several sheaths last night, my first night with the machine. I will make a couple of new sheaths shortly and post pictures of those.

All of that being said, let me give my experience with sewing machines so people will know what to expect. Last year, I bought a Chinese shoe patcher machine to sew some smaller projects. I got it and spent literally three hours adjusting tweaking and de-burring. I never got it to sew a single good stitch. True to my nature, I got angry and never touched the machine again. That is it. I have never sewed a single successful stitch on a sewing machine of any kind until last night. Prior to receiving my machine, I did watch every video on YouTube about the Outlaw by Ryan Neel and that really helped me to get a good start.

All of that being said, let me give my experience with sewing machines so people will know what to expect. Last year, I bought a Chinese shoe patcher machine to sew some smaller projects. I got it and spent literally three hours adjusting tweaking and de-burring. I never got it to sew a single good stitch. True to my nature, I got angry and never touched the machine again. That is it. I have never sewed a single successful stitch on a sewing machine of any kind until last night. Prior to receiving my machine, I did watch every video on YouTube about the Outlaw by Ryan Neel and that really helped me to get a good start.