You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Finally finished one.

- Thread starter Bill Vining

- Start date

Sean Jones

Well-Known Member

Very nice!

Stang Bladeworks

KNIFE MAKER

Wow that looks great. Sorry no tips here i have never made one. Ekim knives has a great series on youtube about flippers. I would check that out. He has a couple videos on that subject.

Bill Vining

Well-Known Member

Thank you. Glad you like it.

I've done some math on the geometries of the detent and I think I answered my own question. Once I get it all resolved, I'll share the information.

I've done some math on the geometries of the detent and I think I answered my own question. Once I get it all resolved, I'll share the information.

Fabio Santos

Member

Very nice!

Bill Vining

Well-Known Member

I realized that flippers are a totally different animal than your standard liner lock. The detent is is most important. In this knife, I found a few issues. 1. The detent ball was sitting too low in the frame. 2. The detent hole in the blade was too small. 3. The lock bar was cut too thin. After fixing 1 and 2, the action was much better but still not where I want it. When the knife is closed and you put some pressure on the flipper tab, you can see the lock bar flex up and down. Although the flex is minimal, it makes the flipping action a bit less than desired.

EdCaffreyMS

"The Montana Bladesmith"

Sounds like your on top of it! Even after all these years of building flippers, I've come to realize that each one creates its own challenges in terms of "action". To be totally honest, that's part of the enjoyment for me.... always a challenge or two to overcome.

I would be very keen to hear your thoughts on getting the geometry correct Bill and any photos you can share to illustrate would be very much appreciated. I am just starting to try and build a front flipper so very keen to pick up any hints and tips from others experiences

John Wilson

Well-Known Member

Beautiful work!

Bill Vining

Well-Known Member

I would be very keen to hear your thoughts on getting the geometry correct Bill and any photos you can share to illustrate would be very much appreciated. I am just starting to try and build a front flipper so very keen to pick up any hints and tips from others experiences

I will try to explain my thoughts on how the detent should work. Above, I listed 3 issues I was having. I will go through each. I have build many many liner locks but this is my first flipper. As mentioned before, it's a totally different animal and I have a pile of scrap to prove it.

1. Height of the detent in the liner.

The height of the detent needs to be at least the same height as the thickness of your washers. In my case, this is a framelock with scales. If the detent extends more than the thickness of the washers, the blade will bind as the liner gets forced against the scales when opening or closing the knife. If you do not use scales, you can make the detent sit .002 or .003 higher. The additional height will not effect the opening or closing.

2. The size of the detent hole.

Thinking logically, I would want as much of the detent as possible to sit in the hole in the blade. I would also want this fit to be as perfect as possible with no play.

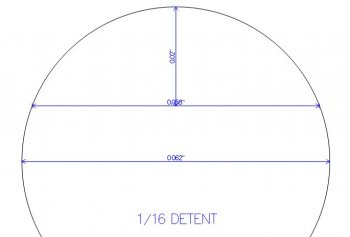

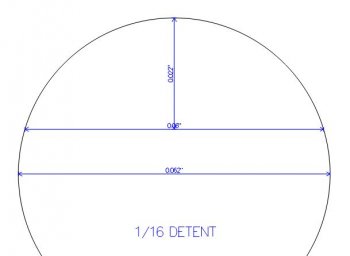

Doing the math:

- .020 detent height. The diameter of the detent where it meets the liner is .058. There are no .058 drills. The closest decimal drill is .055. (#54). The closest metric drill is 1.45 MM (.0571). I don't have any metric drills so I used the #54.

- .022 Detent Height

The diameter of the detent where it meets the liner is .060. The closest decimal drill is .0595. (#53). This seems like the optimal choice to me. I may either shave the lock bar or the scale to allow for the extra height.

3. Lock bar too thin.

Simply change the design to make the lock bar wider.

My last thought.................

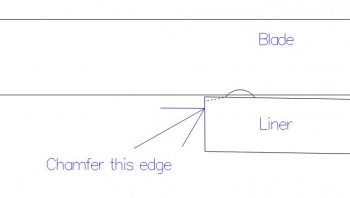

Carefully chamfer the area between your detent and the lock face. Although it's a very small area, it may help your detent sit a bit deeper. Every thousandth counts.

Hopefully I'm on track here and not being to anal about it. Please feel free to let me know what you think of all this.

Thanks!

Don Robinson

Well-Known Member

You got it, Bill! I used CAD to design my first flipper just like that.

Bill, you know this stuff pretty well but for others getting started...

I am using 2MM detent balls for average size and smaller folders. 3/32" for larger ones. I think 2mm balls are slightly easier to work with.

I have been using a #52 for the "pocket" in the blade and will enlarge with a carbide drill after heat treat if I need to. I only enlarge the hole if I need the detent ball to sit lower for more grab. Some do, some don't. Most pocket holes need to go up in size a bit after the #52 initial hole. This is based on visual inspection. If I look and see the detent sitting too high in the closed position, I'll make the hole a bit larger. If there is some flex in the liner lock bar check everything a couple different times as things move each time you assemble.

I will also chamfer the back side of the detent pocket to help get the detent ball seated lower. This is with a dremel and carbide bit. I probably do this on most every one. It helps keep the front edge of the pocket sharp to hold the ball and relieving the back side helps seat the ball.

I am seating the detent ball in the liner to be proud around .023" to .025". Any less and I lose snap at the opening.

I am using 2MM detent balls for average size and smaller folders. 3/32" for larger ones. I think 2mm balls are slightly easier to work with.

I have been using a #52 for the "pocket" in the blade and will enlarge with a carbide drill after heat treat if I need to. I only enlarge the hole if I need the detent ball to sit lower for more grab. Some do, some don't. Most pocket holes need to go up in size a bit after the #52 initial hole. This is based on visual inspection. If I look and see the detent sitting too high in the closed position, I'll make the hole a bit larger. If there is some flex in the liner lock bar check everything a couple different times as things move each time you assemble.

I will also chamfer the back side of the detent pocket to help get the detent ball seated lower. This is with a dremel and carbide bit. I probably do this on most every one. It helps keep the front edge of the pocket sharp to hold the ball and relieving the back side helps seat the ball.

I am seating the detent ball in the liner to be proud around .023" to .025". Any less and I lose snap at the opening.

Bill Vining

Well-Known Member

I have read where some people will offset the hole by .01 or .02 but I've never seen an explanation on why this is done. I don't use an offset myself.

Thanks Bill

I think the offset is done so that the ball never actually falls completely into the hole - it is always wanting to so it creates that "pull in" of the blade but the stop pin is preventing it ever quite getting there. Then I guess the resistance to get back out of the hole is a little less as well (since it never completely sat in there). With a 2mm detent ball (0.0787 inch) I think a 0.02 offset is too much in my experience.

I think the offset is done so that the ball never actually falls completely into the hole - it is always wanting to so it creates that "pull in" of the blade but the stop pin is preventing it ever quite getting there. Then I guess the resistance to get back out of the hole is a little less as well (since it never completely sat in there). With a 2mm detent ball (0.0787 inch) I think a 0.02 offset is too much in my experience.

bladegrinder

Well-Known Member

I have read where some people will offset the hole by .01 or .02 but I've never seen an explanation on why this is done. I don't use an offset myself.

I don't offset my detents either and never had anyone make any comments about the action.

the thing with offsetting the hole is you have 1 chance to do it absolutely perfect

and if it's not.....bam! you've just made a major screw up that could possibly be the death knell of that folder

Hmmm, all valid points and you guys have a lot more experience than me - maybe the whole offset thing isn't necessary after all? I did pick up a tip somewhere for a better offset method - basically with the liners in place and blade installed you replace the stop pin with a slightly smaller one - in my case I am using a 1/8 stop pin so I would place a #31 drill bit in which means the blade can close just that smidgen further. Then drill through the detent hole and into the blade with the blade held firmly closed against the #31 drill stop pin. This results in a very slight offset when you go back to the proper 1/8 stop pin - quite easily.... or so the theory goes.

Bill I am aware this is getting a bit off topic so I applogise if we have hijacked this thread a little but I am really enjoying hearing from yours and others experiences.

Thanks again

Ian

Bill I am aware this is getting a bit off topic so I applogise if we have hijacked this thread a little but I am really enjoying hearing from yours and others experiences.

Thanks again

Ian

Last edited: