You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EvenHeat GT 14-6 score!

- Thread starter Taz575

- Start date

bladegrinder

Well-Known Member

You did good!

1510 on the thermocouple! Took around 100 minutes on high after the slow ramp to 900 over a 60 minute period. I opened it several times, added salt to see if I could see when it melted to check the accuracy of the thermocouple and pyrometer it came with, but even at 1510 on the thermocouple I could still see salt grains. A quick opening dropped the temp to around 1400, and then xlimbed pretty quickly, less than 5 min to be back up to where it was when I opened. 1468 to add salt, 1475, 1485, 1510 to check the salt for melting. When I added the salt, it sizzled and jumped when it hit the floor plate and bricks.

Sean Jones

Well-Known Member

Nice!

I am debating getting some kaowool, coating it with satanite or other refractory (plistix 900, ITC100, etc) and building up a 2-3" thick bed/pad to reduce the volume of the kiln? Would this make any sense? The heating elements are all in the lid, so if I reduce the volume and bring the blades higher, it would be faster?

Smurf masher

Well-Known Member

Smurf masher

Well-Known Member

Yes.. better option. I'm clearly a glass half full of gasoline kinda guy.I prefer to think of it as me celebrating! Lol

Sean Jones

Well-Known Member

I think the Tutu got cooked

My PID supplies from Auberin arrive tomorrow! Is 14ga wire OK for the internal components between the PID and SSR or should I go with 10 or 12 ga wire? I got a short heavy duty extension cord that I am going to cut in half. Female end will come out of the project box to plug the kiln into. Male end will be to connect to the regular power supply. It's a 110V kiln, but I still got the 40amp SSR and heat sink pad/pastes.

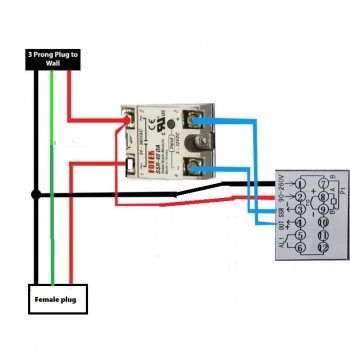

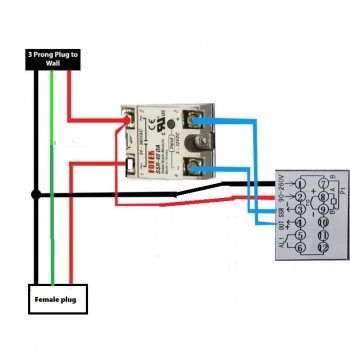

Does this look right for wiring? I cut down a short extension cord so I can use the male end for power to the PID/SSR and the female end to plug the kiln into. I think I can connect the ground all of the way through from the male to female end of the cord? instead of grounding it on the plastic project box? Another suggestion was to put the input power onto terminal one instead of 2 on the SSR and have the cord from #2 on the SSR to go the negative on the female end of the plug.

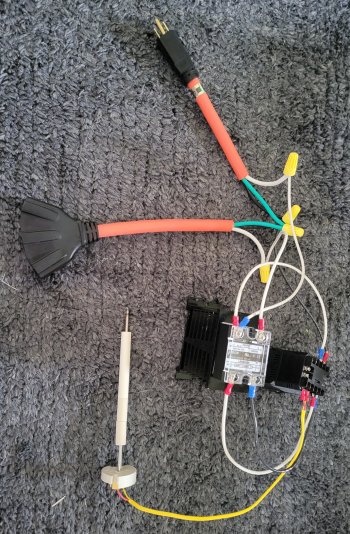

Plugged it into the outlet, TC read 71 for house temp! I gotta drill the kiln sidewall out to insert the new TC and get the components installed into a plastic tool box. The heat sink I got is really tall and wont fit into the project box I got. I should be able to use this setup in a toaster oven for tempering smaller blades, too. Got my new wool today, as well as GreenPatch 421 to coat the top layer of wool, and my AAA oil, so I can start getting the kiln fully running!

Realized I never updated this post! PID is hooked up and running. Maxes out at 1715 degrees. I've done several a few Alabama Damascus blades, some 1095, HHH Damascus blades and some other simple carbon steel with it and it is working great!

I want to get a new set of coils for it and am debating re wiring it to 240V (240V coils are available), so I am looking at rewiring the internals as well and may just run it off the PID and not the regular controller. It takes around 2 hours to get to 1600, so if I want to normalize 52100 or Apex Ultra, it will take a while to heat up on 110V.

I want to get a new set of coils for it and am debating re wiring it to 240V (240V coils are available), so I am looking at rewiring the internals as well and may just run it off the PID and not the regular controller. It takes around 2 hours to get to 1600, so if I want to normalize 52100 or Apex Ultra, it will take a while to heat up on 110V.