You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Epoxy Curing Box?

- Thread starter tkroenlein

- Start date

Chris Railey

Well-Known Member

Do you miss making bows? I do not think I do. If one thinks making knives is expensive they should try making laminated reflex deflex longbows. Toward the end I went back to making all wood bows and I enjoyed that much better. I still have the first and last bow I made though.Well I'm up at work in Prudhoe bay with ambient temp right now around -30 tomorrow is supposed to be around -50 now add some wind chill and a 65 deg shop sounds balmy ! Luckily my shop at home is heated but as mentioned obove by Chris i also used to be a Bowyer and still have all my equipment in the corner of my shop. My heat box that i cured bows in has a thermastat in it and ran 4 light bulb fixtures with 100 wat bulbs,it is made from plywood and lined with the silver bubble insulation. I think a box about the size of a cooler or foot locker well insulated with a thermostat and one light bulb would work just fine for a unheated shop as long as you keep your epoxy in a heated area and also mix and apply in a warm area.

AkWildman

Well-Known Member

Just wasn't any profit in it,especially in Alaska were you have to ship everything in .Do you miss making bows? I do not think I do. If one thinks making knives is expensive they should try making laminated reflex deflex longbows. Toward the end I went back to making all wood bows and I enjoyed that much better. I still have the first and last bow I made though.

I had to type short last night. But what I did on these last four was glue up at about 65-70 degrees under a heat lamp. I have a thermometer right there on the bench. Then I brought them in to cure in a high area of our house where our woodstove is. I had them right above the woodstove, but once had some (unstabilized) antler really dry out there and pull away from a bolster. So I don't let them cure there anymore like I used to. I'd hate to see that happen, but the chances of that happening overnight might be slim. But I can I can do that at our place because that room is shared space with outside stuff anyway.

I read somewhere that you need to wait till the epoxy starts to cure before you heat it up to speed up the drying time. Not sure if thats true but its what I've been doing.

Also with the heat box in a cold shop it's like creating a warm room inside a cold room like forges and kilns etc, right. So I was thinking firebrick would keep it super toasty and an extra layer of insulating foam on the outside might help. I think I remember seeing your shop in a pic you posted and it looks like you have the room out there.

And my after thought last night was since you guys want to keep you house and work area separate, you might be able to have a clean alternative by bringing them in the house when they start to cure in a small breifcase or nice computer bag and stick them up high somewhere.

Just some thought joggers I have from dealing with cold weather.

I read somewhere that you need to wait till the epoxy starts to cure before you heat it up to speed up the drying time. Not sure if thats true but its what I've been doing.

Also with the heat box in a cold shop it's like creating a warm room inside a cold room like forges and kilns etc, right. So I was thinking firebrick would keep it super toasty and an extra layer of insulating foam on the outside might help. I think I remember seeing your shop in a pic you posted and it looks like you have the room out there.

And my after thought last night was since you guys want to keep you house and work area separate, you might be able to have a clean alternative by bringing them in the house when they start to cure in a small breifcase or nice computer bag and stick them up high somewhere.

Just some thought joggers I have from dealing with cold weather.

I had a basement shop for awhile and it stayed around 65 in the winter and I had lots of issues with epoxy until I started using a desk lamp for heat. The difference in cure rate between 65 and 70 seems to be huge. It’s weird. My experience has been, yours maybe different, that if an epoxy has has had a “cold start” and 12 hours later you try and kick it up with heat , it doesn’t work that well. In other words make sure it is warm enough from the start. I always make sure my stuff is at least 70 degrees warm.

any cheap desk lamp or reflector type lamp with a 60 watt bulb will easily heat up a knife handle for a nice warm cure overnight. I did that for every knife in that shop during the winter. Don’t overthink this. A cardboard box with a trouble light will give you room for several.

anymore if I want a little heat for a knife I turn on my knife oven until it gets to 150, turn it off and put the knife in and close the door overnight.

any cheap desk lamp or reflector type lamp with a 60 watt bulb will easily heat up a knife handle for a nice warm cure overnight. I did that for every knife in that shop during the winter. Don’t overthink this. A cardboard box with a trouble light will give you room for several.

anymore if I want a little heat for a knife I turn on my knife oven until it gets to 150, turn it off and put the knife in and close the door overnight.

tkroenlein

Well-Known Member

My whole thinking with the aluminum box was to prevent the shop burning down. I'm a worst case scenario kinda guy. (Not a lot of fun at parties but you'll never leave a new pair of gloves in the woods if you're with me.  ) I figured a 100W bulb would be plenty.

) I figured a 100W bulb would be plenty.

Bruce McLeish

Well-Known Member

That's a pretty good idear, there Gliden. Pretty cheap as well as temperature control. Good one.

Drew Riley

Well-Known Member

I've just put a ceiling mounted heater in my shop that keeps it at a minimum of 50F while I'm not in there, but I've been thinking about the need for something similar just to help keep my adhesives at a more consistent temp.

My plan was to just use an old insulated cooler with a small incandescent bulb and a cheap PID controller.

My plan was to just use an old insulated cooler with a small incandescent bulb and a cheap PID controller.

tkroenlein

Well-Known Member

tkroenlein

Well-Known Member

Oh now come guys...are you all so troll proof you're gonna let this slide?

Chris Railey

Well-Known Member

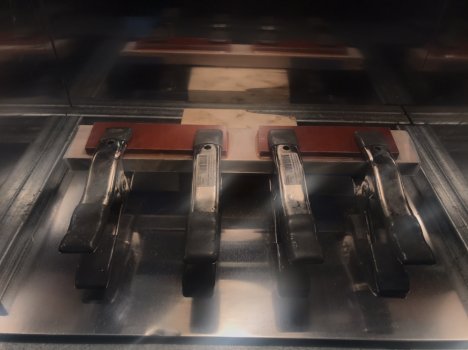

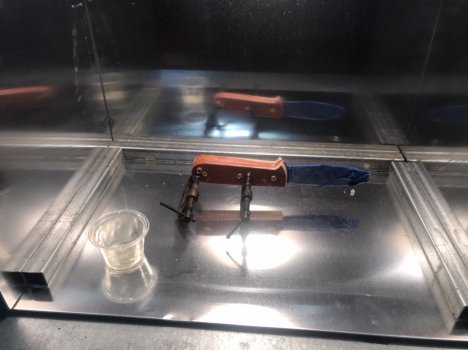

I am actually impressed with the way you put it together in absence of a TIG rig. The square tube was smart.

bladegrinder

Well-Known Member

No diamond plate?

tkroenlein

Well-Known Member

We have had ridiculous amounts of that tubing get scrapped in the past. When I'm going for pretty I use structural pop rivets. But it's easy to build square like this.I am actually impressed with the way you put it together in absence of a TIG rig. The square tube was smart.

tkroenlein

Well-Known Member

Diamond plate is expensive. I can get all the .090" and .125" aluminum I want for $.48/lb., so long as it's under 30" or so in width.No diamond plate?

tkroenlein

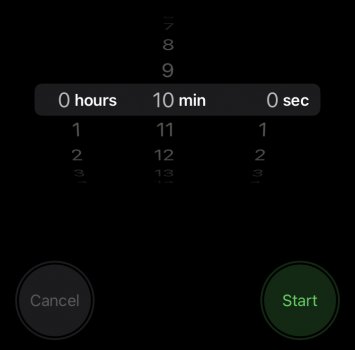

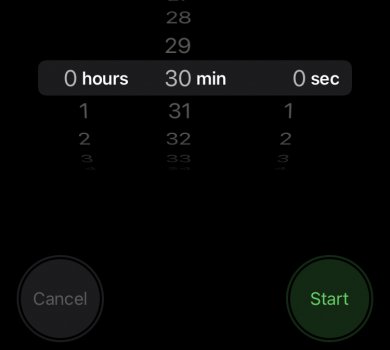

Well-Known Member

tkroenlein

Well-Known Member

chrisstaniar

Well-Known Member

I had a basement shop for awhile and it stayed around 65 in the winter and I had lots of issues with epoxy until I started using a desk lamp for heat. The difference in cure rate between 65 and 70 seems to be huge. It’s weird. My experience has been, yours maybe different, that if an epoxy has has had a “cold start” and 12 hours later you try and kick it up with heat , it doesn’t work that well. In other words make sure it is warm enough from the start. I always make sure my stuff is at least 70 degrees warm.

any cheap desk lamp or reflector type lamp with a 60 watt bulb will easily heat up a knife handle for a nice warm cure overnight. I did that for every knife in that shop during the winter. Don’t overthink this. A cardboard box with a trouble light will give you room for several.

anymore if I want a little heat for a knife I turn on my knife oven until it gets to 150, turn it off and put the knife in and close the door overnight.

I second this. My shop is in my walkout basement and the temp w/o heat is in the low 60's or less on cold days. Epoxy curing slows way down, but if I bring it upstairs the cure is much better.

The temp you've got there should be perfect.