You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Enco surface grinder

- Thread starter BobbyD

- Start date

Jon Buescher

Well-Known Member

oooooohhhhh! I am jealous!

EdCaffreyMS

"The Montana Bladesmith"

I'd jump on it.

WAY back when I was in the market for a surface grinder, I did a LOT of research. Long story short, all the import 6x12 models sold in the U.S. come out of the same barge factory off the coast of China. There are 3 distributors, 2 on the west coast, and 1 on the east coast. The SGs come in shipping containers in generic form. The orders from the "higher end" sellers are uncrated, painted in the company colors, stickers/pates applied, then recrated and shipped to the end sellers. These are the units that sell for $1,500 and up. Smaller outlets, and places like Harbor Freight, just have the machines forwarded to them without any uncrating or painting, and do any stickers or name plates in house. Which means when you see a 6x12 SG selling for $2K+, it's the same one you can get from a discount outlet for $1K or sometimes less. All you get for the extra $$$ is a paint job and stickers/name plates.

Me? I purchase a Harbor Freight SG over 20 years ago, for $950 which included freight. I spent another $150 or so converting it to 2x72" belts..... and knock on wood....she's been doing a great job ever since.

WAY back when I was in the market for a surface grinder, I did a LOT of research. Long story short, all the import 6x12 models sold in the U.S. come out of the same barge factory off the coast of China. There are 3 distributors, 2 on the west coast, and 1 on the east coast. The SGs come in shipping containers in generic form. The orders from the "higher end" sellers are uncrated, painted in the company colors, stickers/pates applied, then recrated and shipped to the end sellers. These are the units that sell for $1,500 and up. Smaller outlets, and places like Harbor Freight, just have the machines forwarded to them without any uncrating or painting, and do any stickers or name plates in house. Which means when you see a 6x12 SG selling for $2K+, it's the same one you can get from a discount outlet for $1K or sometimes less. All you get for the extra $$$ is a paint job and stickers/name plates.

Me? I purchase a Harbor Freight SG over 20 years ago, for $950 which included freight. I spent another $150 or so converting it to 2x72" belts..... and knock on wood....she's been doing a great job ever since.

Last edited:

JeremyBartlett

Well-Known Member

I'd grab that i a sec. I'm still looking for one as well. Id ask if it has a mag chuck that comes with it as those typically run a couple hundred bucks

JeremyBartlett

Well-Known Member

If it doesn't have the chuck it can give you some leverage to talk them down a bit

EdCaffreyMS

"The Montana Bladesmith"

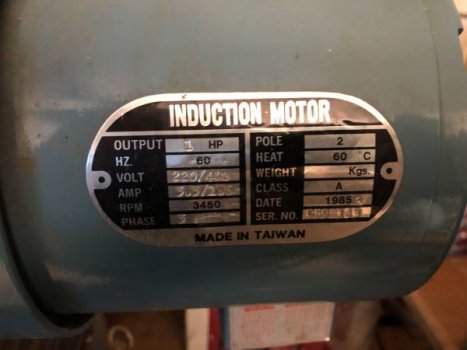

There is a magchuck in the pic. But looking at the motor plate.... it appears it is 220/440, 3 phase. Am I seeing that correctly? If so, that leads me to believe it is a 6x18 machine? Enco has been gone for a few years, but if memory serves, the only 3 phase SG they had in their catalogs were 6x18" and larger. That's not a bad thing at all, in fact there have been many time I wished I had gotten a 6x18. Just have to ask the seller questions to get all the info, and unless you already have the capacity to use 3 phase..... find out if it's doable for you.

JeremyBartlett

Well-Known Member

You can always get a kbac vfd for it to convert it to 3 phase, or a little cheaper option would be to get a phase converter. Just make sure the phase converter matches the hp of the motorI was afraid of that. I can’t provide 3phase. Waiting for there response.

Gliden07

Well-Known Member

You can also get a Rotary Phase Converter. If you have or can get a 3 PH motor cheap you can buy the electronic/electrics kit on eBay depending on size pretty cheap. Much less than a KBAC VFD. If you can source a cheap motor. You can also do what they call an "ADD A PHASE" converter. Problem with those is you loose more power with them vs the Rotaty version.I was afraid of that. I can’t provide 3phase. Waiting for there response.

bladegrinder

Well-Known Member

If you get this Bobby and get a VFD to run the 3 phase motor you might want to get a VFD with a digital read out,

I just set up a used surface grinder, and after reading up on these machines I kind of gathered it's best to keep the spindle

speed at what the motor is rated for. my motor is rated for 50 hertz so that's what I have the VFD set for.

with a VFD like the kbac you'll be guessing whether or not your running to slow, for good operating finishes on the steel or over speeding with possible negative effects on the steel or the motor and spindle bearings.

I just set up a used surface grinder, and after reading up on these machines I kind of gathered it's best to keep the spindle

speed at what the motor is rated for. my motor is rated for 50 hertz so that's what I have the VFD set for.

with a VFD like the kbac you'll be guessing whether or not your running to slow, for good operating finishes on the steel or over speeding with possible negative effects on the steel or the motor and spindle bearings.

Drew Riley

Well-Known Member

I have a 1hp 3phase surface grinder and use the same 2hp VFD that I run my knee mill with. I just make sure that it's running at least 60hz. I've also run it a little faster at times, though I wouldn't overspeed it like that with a stone wheel (mine is converted to belts). Just understand that if your VFD is rated for more than 1hp, it will still drive the motor, but it built in circuit protection from the VFD will still be rated for a 2hp motor. In practice, this really shouldn't be an issue, but just something to keep in mind. Just keep an eye on motor temps if you're using it for extended periods.Appreciate everyones input. The tag says it 60 hertz so could I run it both off vfd that my grinder is using?

And I'll state again: Stone wheels have an RPM limit, so I wouldn't go past 60Hz. When stone wheels blow up, they BLOW UP. Like a frag grenade. I failed to ring test a wheel when I first got my surface grinder (before I converted it) and a wheel blew apart as soon as the spindle got up to speed. I never did find all the pieces. The VFD I use has the displayed output set to Hz, so I know if I'm running 60Hz or not. My grinder VFD, however, has a dial from 0 to 100, where 100 is 120hz (2x speed). So just make sure you know where 60Hz is.

Drew Riley

Well-Known Member

It wasn't terribly difficult. Here's a video I shot giving an overview of what I initially did:Thanks Drew. Is it difficult to change over to belts and what was your cost?

IIRC, it was about $200 for the contact wheel, maybe $40ish for the tracking wheel, and maybe $40 for the rest of the odds and ends if you don't already have some scrap laying around. I've since changed the tracking arm to a piece of 2-1/2" x 5/8" bar since the original square tube offset my tracking wheel from the contact wheel too much. I also added a handle out on the end for easier belt changes. If I had it to do all over again (and I may still do this when I have an extra $250 laying around), I'd get a 1-1/8 wide wheel (If you use 1" belts, this just helps keep the belt from rolling over the corner), and I'm not sure I'd add the serrations, as I think I MIGHT get a smoother surface finish without them. If you're hogging a lot of material off per pass, definitely get serrations, as they cut better and keep your work cooler, but I'm normally taking very little off per pass, and will likely add flood coolant down the line anyway.

Drew Riley

Well-Known Member

Drew Riley on Instagram: "Sometimes it’s the little things: added a simple handle to my surface grinder belt assembly for changing belts. Not sure why I didn’t make one to begin with. Also fixed a couple of other issues that have been nagging me for

23 likes, 0 comments - rileyknifeandtoolNovember 17, 2020 on : "Sometimes it’s the little things: added a simple handle to my surface grinder belt assembly for changing belts. Not sure why I didn’t..."

www.instagram.com

www.instagram.com

There's a pic of my latest setup.