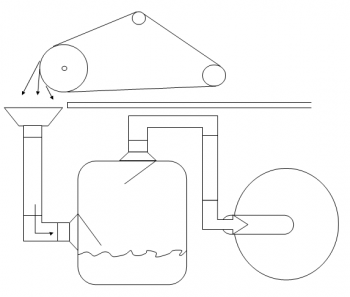

So I have done some checking through old threads about dust collection and spark arrests. I believe I will use a water trap before my craftsman dust collector for the sanding of handles and materials and finishing. For steel grinding I am thinking and a shop vac with water in it.

I am in a garage at a condo association so I am limited to what I can do.

Thoughts and input wound be great.

I am in a garage at a condo association so I am limited to what I can do.

Thoughts and input wound be great.