You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dust collection

- Thread starter wyoske

- Start date

Frank Niro

KNIFE MAKER

Use a squiril cage fan with metal piping to the outside. Do not use cloth bags on any part of it unless this will only be for your buffing wheel. Frank

I struggled with an acceptable design for a long time and reviewed all the threads on the subject. I never liked the potential danger of introducing a spark into a dusty airstream, it's just too risky for me. I finally settled on a portable dust collector that sits on the floor near the source of dust. When the inlet side of the unit is placed near the grinder, it sucks dust and smoke across the grinder and through the filters, but because it is not an enclosed "system", the potential for explosion of fire is near zero. My shop used to have dust on everything but now there is dust only in a 4-5 foot diameter circle around the grinder. It is a minimal amount and only requires a quick vacuum cleanup once in a while, and the rest of the shop is dust free. The pre-filter needs cleaned frequently with a vacuum, or sometimes I just take it outside and beat it with a stick to remove the dust (it's good therapy). I purchased a model G0573 floor unit for $644 at www.Grizzly.com. They also sell ceiling mount units that are less costly and might work just as well but I can recommend this one for sure. I run it on low (1500 CFM) and it pulls quite a bit of air. I can use it anywhere in the shop because it is on rollers and there is no installation. It does take up floor space which is annoying and if you have multiple sources of dust it might not be what you want, but I love mine and I can sleep at night knowing there is nothing smoldering. Hope this helps.

EdCaffreyMS

"The Montana Bladesmith"

First thing I would do is hang a 5 gallon bucket of water just below the grinder attachment (I mounted a metal hanger to the bench the grinder sits on). Put a good squirt of dishwashing liquid in the water. That will catch a lot of the "swarf". Nothing will catch it all, so a good respirator is a must. As for a general type dust collector, I've personally never had much luck with them.....I've owned a couple of different systems over the years....first one was basically a waste of money as it was too whimpy to collect anything, and the second one nearly burnt the shop down (it was my fault). So now I have a single shop vac hooked up under the grinder bench, and only turn it on for non metallic grinding.

rhinoknives

Well-Known Member

Another vote for the five gallon bucket of water on the floor or hung just below the grinding wheel or platen.

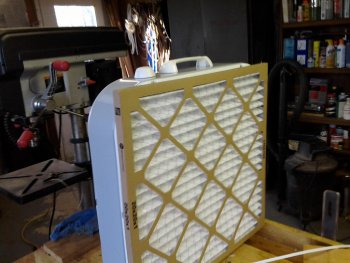

The other least expensive and very effective was to build a dust collector is to buy a 24' x 24" box fan and put some angle iron around it or just Duct tape a paper filter to it. When the filter loads up take it outside and tap the big checks out over a trash can and put it back on the box fan a time or two before you switch to a new filter. Non of this is 100% Like Ed said, Use a quality respirator too.

The other least expensive and very effective was to build a dust collector is to buy a 24' x 24" box fan and put some angle iron around it or just Duct tape a paper filter to it. When the filter loads up take it outside and tap the big checks out over a trash can and put it back on the box fan a time or two before you switch to a new filter. Non of this is 100% Like Ed said, Use a quality respirator too.

Freds Edge

Well-Known Member

Kurt Krueger

Well-Known Member

I took my dust collection a bit further for a couple of reasons,,, safety, not wanting to get sparks in contact with any dust and to keep abrasive dust off of my lumber and woodworking equipment. My shop is a woodshop first, knife shop second.

I don't have any pictures, but can add some later.

I built a stand for my KMG and framed a tent using 3/4" PVC pipe and poly plastic sheeting to enclose the grinder on all sides, leaving a hanging flap to act as a door. In lieu of the pail full of water, I use a 30 gallon steel trash can with about 6" of water in the bottom. I fashioned a lid out of plywood and use a 3' section of 6" steel duct as a "down-pipe" The bottom end of the pipe is just a couple of inches above the surface of the water in the can. A 4" dust collection fitting acts as a suction port and connects my dust collector (2 hp, ~1000 CFM wood dust collector, similar to the Grizzley mentioned above) to the plywood lid, just adjacent the down-pipe. Inside the can, on the suction port is a 90° elbow that forces a vortex in the airflow to further separate solid particulate.

In addition I also have a whole-shop filter, basically a plywood box with HEPA filters on two sides and an old furnace fan to draw air through.

The system seems to work quite efficiently and I haven't noticed any additional dust in the shop.

Hope this helps.

-Kurt

I don't have any pictures, but can add some later.

I built a stand for my KMG and framed a tent using 3/4" PVC pipe and poly plastic sheeting to enclose the grinder on all sides, leaving a hanging flap to act as a door. In lieu of the pail full of water, I use a 30 gallon steel trash can with about 6" of water in the bottom. I fashioned a lid out of plywood and use a 3' section of 6" steel duct as a "down-pipe" The bottom end of the pipe is just a couple of inches above the surface of the water in the can. A 4" dust collection fitting acts as a suction port and connects my dust collector (2 hp, ~1000 CFM wood dust collector, similar to the Grizzley mentioned above) to the plywood lid, just adjacent the down-pipe. Inside the can, on the suction port is a 90° elbow that forces a vortex in the airflow to further separate solid particulate.

In addition I also have a whole-shop filter, basically a plywood box with HEPA filters on two sides and an old furnace fan to draw air through.

The system seems to work quite efficiently and I haven't noticed any additional dust in the shop.

Hope this helps.

-Kurt

Ive taken the 5 gallon bucket of water a little further. We bought a vacuum cleaner called a "rainbow" that doesnt use bags or cyclonic action to trap dirt, it draws through a tank water and therefor doesnt clog at all or lose suction. What I did was take some misc parts from rockler and a 5 gallon bucket and lid from a big box store.

Mounted right under the belt grinder will be a "tabletop dust fitting ( http://www.rockler.com/tabletop-dust-fitting ) with a short run of hose that goes to 5 gal bucket lid. the same fitting will have a smaller pipe going down to bottom of the bucket. On the other side of the lid is another fitting that you attach shop vac hose to. Then you fill bucket about half full of water. The inlet from dust fitting goes below the level of the water and the shop vac side does not which should create enough vacuum in the bucket to draw air in thru the water to trap particles so the shop vac filter doesnt get clogged.

Im still putting it together, but ill try and get some pics when done.

Mounted right under the belt grinder will be a "tabletop dust fitting ( http://www.rockler.com/tabletop-dust-fitting ) with a short run of hose that goes to 5 gal bucket lid. the same fitting will have a smaller pipe going down to bottom of the bucket. On the other side of the lid is another fitting that you attach shop vac hose to. Then you fill bucket about half full of water. The inlet from dust fitting goes below the level of the water and the shop vac side does not which should create enough vacuum in the bucket to draw air in thru the water to trap particles so the shop vac filter doesnt get clogged.

Im still putting it together, but ill try and get some pics when done.

JawJacker

Well-Known Member

Motor City Mike

Well-Known Member

Ive taken the 5 gallon bucket of water a little further. We bought a vacuum cleaner called a "rainbow" that doesnt use bags or cyclonic action to trap dirt, it draws through a tank water and therefor doesnt clog at all or lose suction. What I did was take some misc parts from rockler and a 5 gallon bucket and lid from a big box store.

Mounted right under the belt grinder will be a "tabletop dust fitting ( http://www.rockler.com/tabletop-dust-fitting ) with a short run of hose that goes to 5 gal bucket lid. the same fitting will have a smaller pipe going down to bottom of the bucket. On the other side of the lid is another fitting that you attach shop vac hose to. Then you fill bucket about half full of water. The inlet from dust fitting goes below the level of the water and the shop vac side does not which should create enough vacuum in the bucket to draw air in thru the water to trap particles so the shop vac filter doesnt get clogged.

Im still putting it together, but ill try and get some pics when done.

Sounds like a bong :biggrin:

I went with a squirrel cage, duct work and a furnace filter. I was on the local fire dept for 6 years and am not particularly worried about sparks and dust. The air flow in mine has two 90 degree turns to negotiate to get to the exhaust and there is no grain dust in my garage that I would have to worry about exploding. In the event that a spark could somehow travel to the furnace filter and catch fire, I have a fire extinguisher within 3 feet.

rhinoknives

Well-Known Member

I bought, and hung up, a Fire Extinguisher. I also purchased a JDS air filtration unit.

Having two fire extinguishers is even better! But one is better than none! I had a fire start in a shop Vac after a dummy move once after I ground some Damascus steel right after a few handles of Ironwood shavings without dumping out the Vac! Seeing smoke come pouring out of the exhaust vent in your shop Vac makes for some real inspiration to go get than fire extinguisher Pronto!:happy:

mchamblades

New Member

I realize this is an old post but as a new knife maker (long time lurker) I wanted to say thanks to everyone for this advice. I was trying to figure out how to improve the air quality in my garage, and more importantly my lungs, without breaking the bank. After grinding on my third knife shaped object this week, I got tired of the metal taste in my mouth and knew it couldn't be good for my lungs. So, I started looking for forum advice on respirator models but didn't think I could currently afford to outfit the garage with a dust collection setup. I think the box fan with air filter next to my grinder is a winner and I'm looking forward to trying it out this weekend.

John Wilson

Well-Known Member

Dust collection is a good thing, but in no way a replacement for wearing a respirator. The dust collector keeps your shop a whole lot cleaner, but it's not doing jack for your lungs. My advice: don't even think about dust collectors and respirators in the same thought process. I can't tell from your post whether you went with a respirator or if you only went with a box fan and some filters. I apologize for being preachy, but I hope you aren't doing the box fan thing with no respirator.

Respirators are cheap. Even great respirators are cheap. The most expensive respirator is cheaper than lung cancer.

Respirators are cheap. Even great respirators are cheap. The most expensive respirator is cheaper than lung cancer.

Last edited:

After watching Ed's videos a while back - I went the same route as he suggests. I use a bucket of water and a shop-vac. I have my shop vac connected to a dust deputy and connected them to furnace vent I had lying around. I only use the dust collection for handle work. I think a set up where the vacuum hits water first would be suitable for metal work. I've used the box fan in the past and that's a nice supplement as well - just doesn't work for me due to space limitations. In my particular setup, handle dust is kept to a nice minimum. Metal dust does tend to cover the grinder and surrounding 2 feet or so, but that's easy enough cleanup. Ultimately for me, this is just my hobby, so budget and space are the driving factors for dust collection.

John Wilson

Well-Known Member

I run my dust collector through a water bin on the way to the blower. It works like a champ.