I hope this fits in the W.I.P category since it is a knife making related machine. I wanted to add a disc grinder to my shop. I built my own belt grinder a few years ago and that was a fun project. A disc grinder looked a lot simpler so I started gathering parts. I looked at what was offered to buy as complete units and used bits and pieces of designs from different models. The Nielson disc system is an awesome idea so I incorporated that into my machine. I also used a few features of the Beaumont grinder as well. I worked on this project off and on for the last few months, but I documented the build along the way. So here goes! The material I used was 6061 Aluminum and 1018 cold roll.

Let’s start with the base. It is .500” thick aluminum.

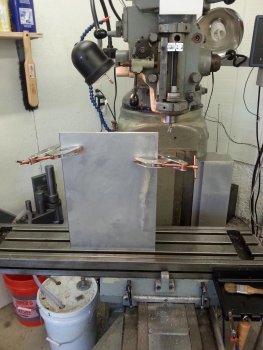

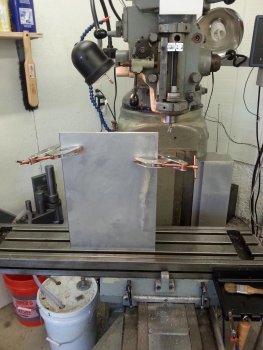

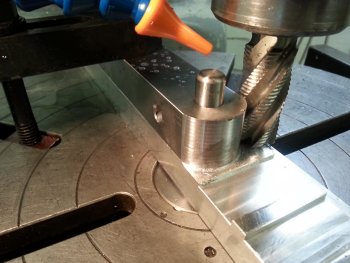

Here are a few shots of squaring up the base plate.

Now the edges are square and the plate is sized. It is time to drill and tap some holes.

I didn’t take any pictures of the machining, but this is the riser block that the motor sits on.

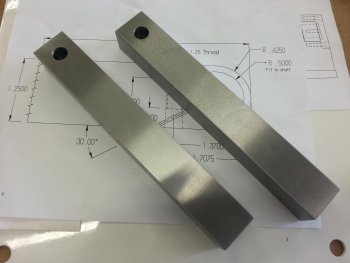

Next will be the clamp arm posts that will hold the work rest. They are 2” square 1018 cold roll. I machined them in pairs so they are identical and everything will stay square.

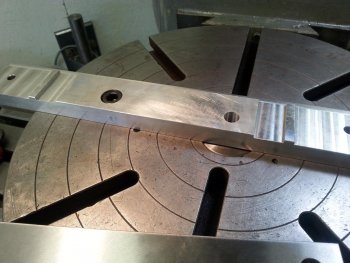

I decided to surface grind the clamp arm posts. These will be black oxide coated.

Let’s start with the base. It is .500” thick aluminum.

Here are a few shots of squaring up the base plate.

Now the edges are square and the plate is sized. It is time to drill and tap some holes.

I didn’t take any pictures of the machining, but this is the riser block that the motor sits on.

Next will be the clamp arm posts that will hold the work rest. They are 2” square 1018 cold roll. I machined them in pairs so they are identical and everything will stay square.

I decided to surface grind the clamp arm posts. These will be black oxide coated.

Last edited:

I would like to get a 6" or 8" table somday but this does all i need and then some.

I would like to get a 6" or 8" table somday but this does all i need and then some.