Darrin Sanders

Moderator

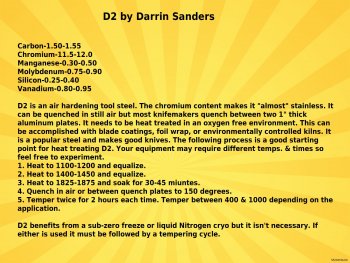

Carbon-1.50-1.55

Chromium-11.5-12.0

Manganese-0.30-0.50

Molybdenum-0.75-0.90

Silicon-0.25-0.40

Vanadium-0.80-0.95

D2 is an air hardening tool steel. The chromium content makes it "almost" stainless. It can be quenched in still air but most knifemakers quench between two 1" thick aluminum plates. It needs to be heat treated in an oxygen free environment. This can be accomplished with blade coatings, foil wrap, or environmentally controlled kilns. It is a popular steel and makes good knives. The following process is a good starting point for heat treating D2. Your equipment may require different temps. & times so feel free to experiment.

1. Heat to 1100-1200 and equalize.

2. Heat to 1400-1450 and equalize.

3. Heat to 1825-1875 and soak for 30-45 miuntes.

4. Quench in air or between quench plates to 150 degrees.

5. Temper twice for 2 hours each time. Temper between 400 & 1000 depending on the application.

D2 benefits from a sub-zero freeze or liquid Nitrogen cryo but it isn't necessary. If either is used it must be followed by a tempering cycle.

Chromium-11.5-12.0

Manganese-0.30-0.50

Molybdenum-0.75-0.90

Silicon-0.25-0.40

Vanadium-0.80-0.95

D2 is an air hardening tool steel. The chromium content makes it "almost" stainless. It can be quenched in still air but most knifemakers quench between two 1" thick aluminum plates. It needs to be heat treated in an oxygen free environment. This can be accomplished with blade coatings, foil wrap, or environmentally controlled kilns. It is a popular steel and makes good knives. The following process is a good starting point for heat treating D2. Your equipment may require different temps. & times so feel free to experiment.

1. Heat to 1100-1200 and equalize.

2. Heat to 1400-1450 and equalize.

3. Heat to 1825-1875 and soak for 30-45 miuntes.

4. Quench in air or between quench plates to 150 degrees.

5. Temper twice for 2 hours each time. Temper between 400 & 1000 depending on the application.

D2 benefits from a sub-zero freeze or liquid Nitrogen cryo but it isn't necessary. If either is used it must be followed by a tempering cycle.