Hello all, I don't have a cutoff saw and thinking about getting one to cut metal stuff with. How good are they? I'm sure they'd do good on small stuff <1/4", but what about cutting a 3/4"X6" bar - do they handle that type of cut very well?

What about this one:

https://www.amazon.com/dp/B00NI2CF28/

I've not made up my mind yet on ordering, just wanted some input for the folks here.

Ken H>

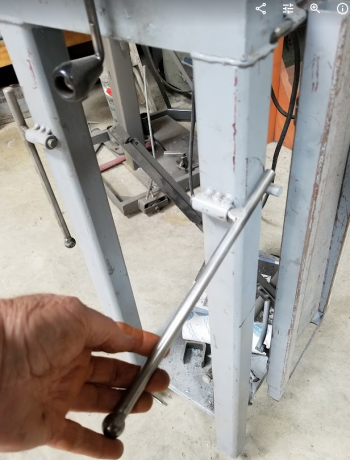

I've had an Evolution cold cut off saw for over a decade and love it. I initially got it to do a bunch of light tubular fabrication and now use it almost on a daily basis. However, it seems to me that in a knife making shop an abrasive or cold cut off saw has less priority than other knife-focused equipment (e.g. 2x72 / HT oven, etc) BUT, a cut off saw helps making knife making equipment easier (tables, stands, jigs, etc)

Pros: Cleaner than abrasive, no showers of sparks (no fire issue), cuts clean & more accurate than abrasive, does not burn the metal to cut, somewhat less noisier than an abrasive saw'

Cons: Somewhat limited in cutting thickness / size (though I've routinely cut 3/4" material & 3" diameter steel - blade travel speed is critical), blades are expensive

Like so many pieces of shop equipment a cut off saw has it's place and limitations. It won't take the place of either a vertical or horizontal bandsaw. And, yes, the metal chards are mess - though added chip shielding plus a magnetic floor sweeper minimizes the cleanup (certainly a worthwhile tradeoff compared to the abrasive grit all over the shop).

And, FWIW, the use of an

unshieldded angle grinder as a substitute for a cut off saw is dancing with the devil IMHO. Those angle grinder cut off wheels are notorious for exploding. Check out youtube videos, pretty sobering.