Ryan Minchew

Well-Known Member

Before I managed to catch myself on fire Ken Hurst contacted me about building him a slip joint after he saw this one I posted. He's been an extremely patient man while I heal up from the burns and finish up other knives I had in the works.

The pictures show fine silver nail pull studs (?), on the knife for Mr. Hurst they will be gold, the bolster will be bigger, and the handle (crossing fingers) will be blacklip pearl. I have the pearl sitting on the bench and it makes me nervous just looking at it. I've got some pictures loaded up and have more I'll add in a few days, and get caught up to the point I am actually at. My work schedule has kept me from getting these loaded. I have made VERY few folders so my methods are probably a bit different from others.

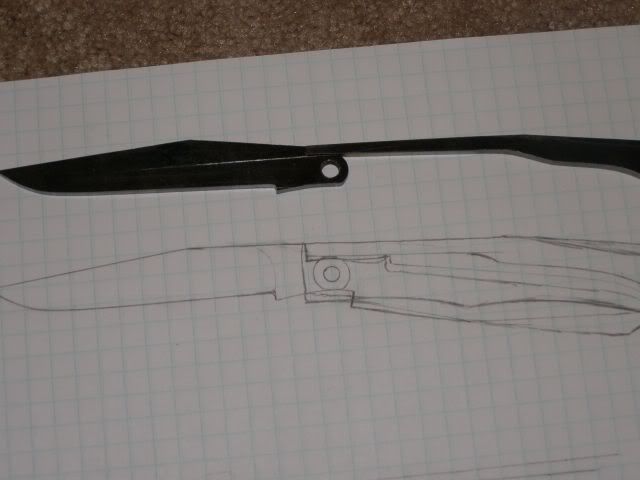

Laying out the pattern

I cut out several to have several to send to Paul Bos.

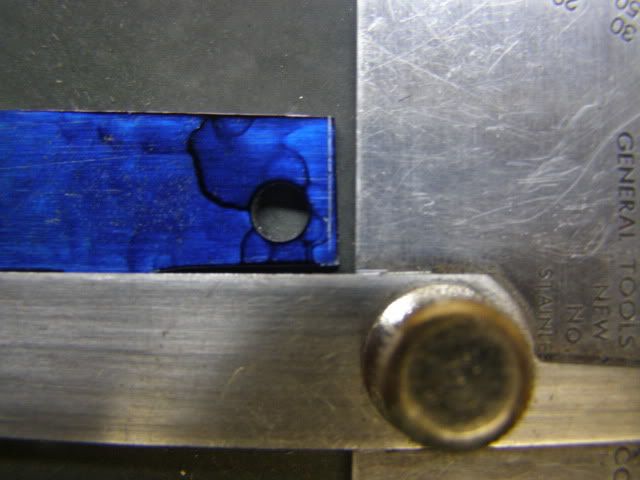

Here I have just cut out blade and spring together. It helps me to do it this way for drilling holes.

Next I squared up the drill press so that my holes will be perpindicular and straight. Hopefully .

.

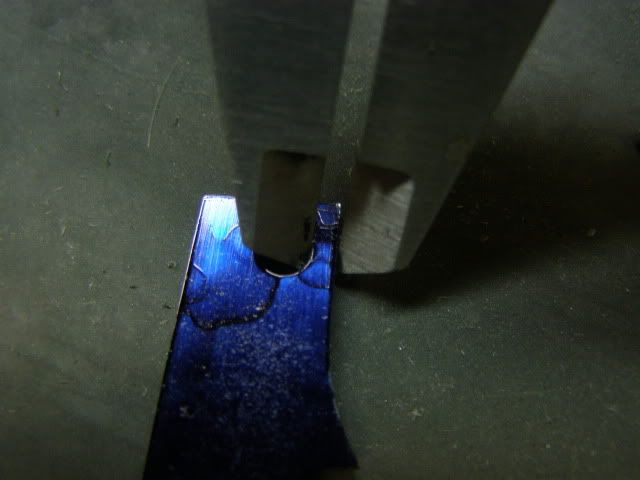

Here I am drilling all the holes with a 3/32" bit. The pivot hole will actually be 3/16" for the phosphorus bronze bushing I use. But the 3/32" is a pilot.

Reaming the holes with a 3/32" reamer using tapping fluid.

The pictures show fine silver nail pull studs (?), on the knife for Mr. Hurst they will be gold, the bolster will be bigger, and the handle (crossing fingers) will be blacklip pearl. I have the pearl sitting on the bench and it makes me nervous just looking at it. I've got some pictures loaded up and have more I'll add in a few days, and get caught up to the point I am actually at. My work schedule has kept me from getting these loaded. I have made VERY few folders so my methods are probably a bit different from others.

Laying out the pattern

I cut out several to have several to send to Paul Bos.

Here I have just cut out blade and spring together. It helps me to do it this way for drilling holes.

Next I squared up the drill press so that my holes will be perpindicular and straight. Hopefully

Here I am drilling all the holes with a 3/32" bit. The pivot hole will actually be 3/16" for the phosphorus bronze bushing I use. But the 3/32" is a pilot.

Reaming the holes with a 3/32" reamer using tapping fluid.