Stormcrow

Well-Known Member

Some more recently completed work.

A forged camp chopper, 80CrV2 steel and TeroTuf handle slabs. The blade is about 10 5/8" long. The customer wanted a large finger choil for choked-up work. It's not the biggest blade I've made by any stretch, but everyone who handled it agreed it was a beast.

tw04 by James Helm, on Flickr

tw04 by James Helm, on Flickr

Kydex sheath.

tw05 by James Helm, on Flickr

tw05 by James Helm, on Flickr

The customer requested an exposed skullcrusher tang and a dedicated lanyard hole. This was a first for me, to build a slab handle with a notch to accommodate a lanyard hole. I say "dedicated" because the flared tube rivets also afford lanyard attachment points.

tw06 by James Helm, on Flickr

tw06 by James Helm, on Flickr

I've been in the very long, slow process of trying to launch a mid-tech stock removal line based on my more popular forged designs. I haven't posted too much about it because I wanted to have everything ready to roll first. I'm finally approaching that point. Along the way I have had small batches of blades waterjet cut and have tweaked my design a bit as I go, getting everything zeroed in to the final product. I have a very small handful of the older style blade designs in various states of completion, most of which are already claimed, before doing a full launch of the line.

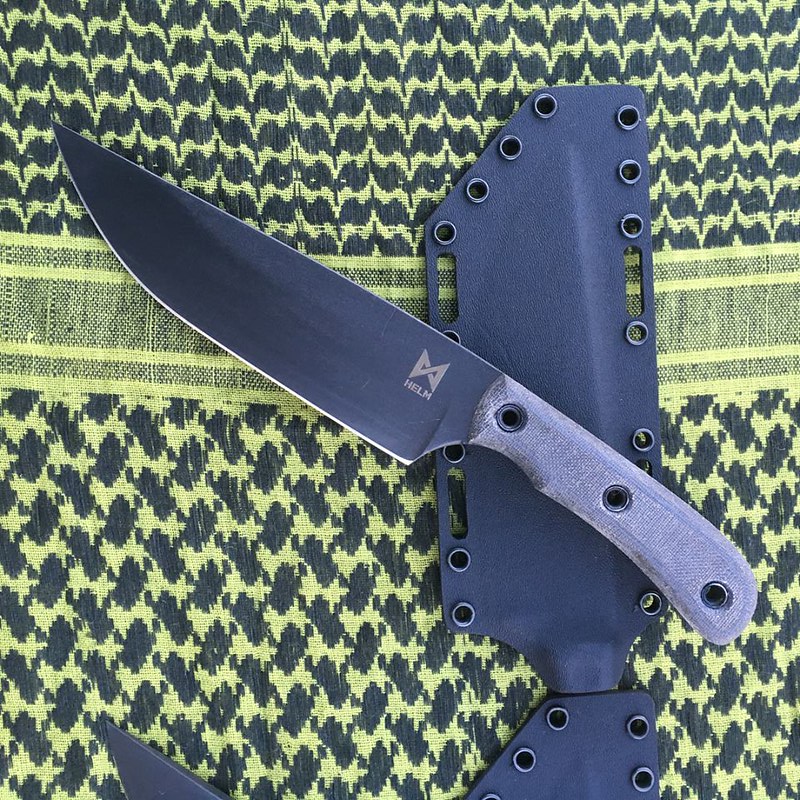

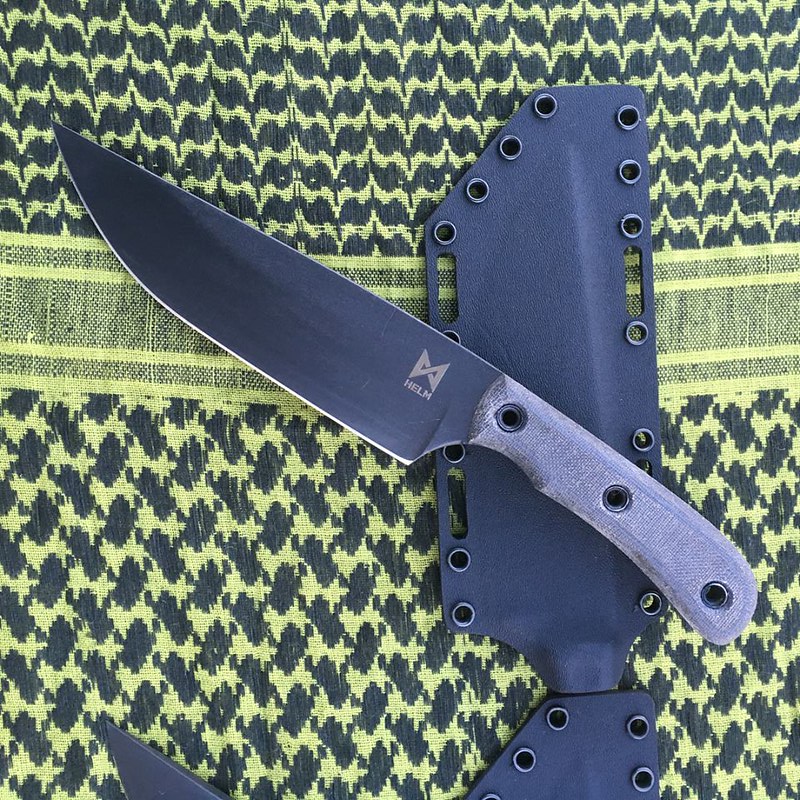

This set of three Benghazi Warfighters was bought by fellow for himself and some family members. The blanks are waterjet cut from 3/16" 80CrV2 steel, ground and heat treated by me, and handle slabs shaped from TeroTuf using jigs and a series of router bits.

bw04 by James Helm, on Flickr

bw04 by James Helm, on Flickr

The blades have a Caswell black oxide finish (the final version will have a coating) with the touchmark laser engraved. The sheaths are standardized, one will fit any of the blades.

bw05 by James Helm, on Flickr

bw05 by James Helm, on Flickr

A couple of hours after picking these up, the customer called up and laid claim to one of the older-style Little Rok mid-techs in progress.

A forged camp chopper, 80CrV2 steel and TeroTuf handle slabs. The blade is about 10 5/8" long. The customer wanted a large finger choil for choked-up work. It's not the biggest blade I've made by any stretch, but everyone who handled it agreed it was a beast.

tw04 by James Helm, on Flickr

tw04 by James Helm, on FlickrKydex sheath.

tw05 by James Helm, on Flickr

tw05 by James Helm, on FlickrThe customer requested an exposed skullcrusher tang and a dedicated lanyard hole. This was a first for me, to build a slab handle with a notch to accommodate a lanyard hole. I say "dedicated" because the flared tube rivets also afford lanyard attachment points.

tw06 by James Helm, on Flickr

tw06 by James Helm, on FlickrI've been in the very long, slow process of trying to launch a mid-tech stock removal line based on my more popular forged designs. I haven't posted too much about it because I wanted to have everything ready to roll first. I'm finally approaching that point. Along the way I have had small batches of blades waterjet cut and have tweaked my design a bit as I go, getting everything zeroed in to the final product. I have a very small handful of the older style blade designs in various states of completion, most of which are already claimed, before doing a full launch of the line.

This set of three Benghazi Warfighters was bought by fellow for himself and some family members. The blanks are waterjet cut from 3/16" 80CrV2 steel, ground and heat treated by me, and handle slabs shaped from TeroTuf using jigs and a series of router bits.

bw04 by James Helm, on Flickr

bw04 by James Helm, on FlickrThe blades have a Caswell black oxide finish (the final version will have a coating) with the touchmark laser engraved. The sheaths are standardized, one will fit any of the blades.

bw05 by James Helm, on Flickr

bw05 by James Helm, on FlickrA couple of hours after picking these up, the customer called up and laid claim to one of the older-style Little Rok mid-techs in progress.