Hey Dogs

I’ve been working on laser etching wooden handles for kitchen/other knives. I’ve tried a bunch of fancy stuff but this simple pattern is the best so far. Actually the FIRST so far 'cause I’m not sure of the sequence. I see two possible ways of doing this.

1) Mount up everything ahead of time with a close to finished look. For me that’s epoxying on the scales, setting pins, sanding and shaping up to 180 or 220. After that put the piece on the engraver and burn away. The laser cuts deep enough so that further fine sanding won’t erase the burn marks. Buffing is ok too. That’s the sequence I followed.

2) Make the scales and engrave ahead of time, then follow typical procedures for attaching, shaping, etc. I think this would require an extra deep burn so as not to lose the etching while shaping. Lots of radius edges to work with, so Maybe 1/8” deep on the burn.

During my experiments I was glad to find that the laser didn’t freak out when it wrote over the brass pins. These were sanded to 180, not polished so maybe that’s why it ran ok. I’d heard that any reflective surface would disorient the burn.

I’d be very happy to hear from anyone doing this kind of thing.

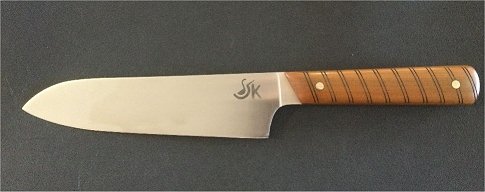

This little santoku is a blank from the Big Dog. These sell pretty well, finished for around $150. Logo (SpoonBowlKnife) is electro etched in a different process. One of the pix is just a show-off of my cool cardboard sheath which I use for distribution.

I’ve been working on laser etching wooden handles for kitchen/other knives. I’ve tried a bunch of fancy stuff but this simple pattern is the best so far. Actually the FIRST so far 'cause I’m not sure of the sequence. I see two possible ways of doing this.

1) Mount up everything ahead of time with a close to finished look. For me that’s epoxying on the scales, setting pins, sanding and shaping up to 180 or 220. After that put the piece on the engraver and burn away. The laser cuts deep enough so that further fine sanding won’t erase the burn marks. Buffing is ok too. That’s the sequence I followed.

2) Make the scales and engrave ahead of time, then follow typical procedures for attaching, shaping, etc. I think this would require an extra deep burn so as not to lose the etching while shaping. Lots of radius edges to work with, so Maybe 1/8” deep on the burn.

During my experiments I was glad to find that the laser didn’t freak out when it wrote over the brass pins. These were sanded to 180, not polished so maybe that’s why it ran ok. I’d heard that any reflective surface would disorient the burn.

I’d be very happy to hear from anyone doing this kind of thing.

This little santoku is a blank from the Big Dog. These sell pretty well, finished for around $150. Logo (SpoonBowlKnife) is electro etched in a different process. One of the pix is just a show-off of my cool cardboard sheath which I use for distribution.

Attachments

Last edited: