brandon0403

Well-Known Member

I thought it would be nice to have one thread where I put all my progress as I start out.

What I have to work with...

Metal cutting band saw from Harbor Freight (adjusted to cut square)

8" buff wheel powered by a 1/3 HP 1725 rpm motor (with green and white rouge)

Beaumont Metal works KMG-PL Grinder with 8x2 contact wheel, Knife Dogs small wheel attachment w/ .75" wheel, and of course the platen attachment and tool rest.

Foley 6" bench grinder and 4th generation Drill Press

Assorted Belts from USAknifemaker.com

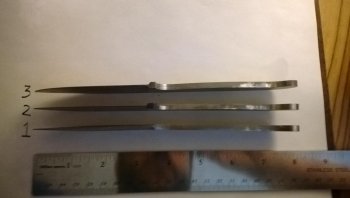

And of course some steel from NewJerseySteelBaron.com (440-C, 154-CM, 1084, and 52100)

I have a question regarding the steel, the 1084 and 52100 arrived pretty warped along the length of the steel bar. Should I be worried about this waviness, is it normal? If it is normal I assume I will have to straighten any blanks I cut from it, any suggestions on how to accomplish this?

What I have to work with...

Metal cutting band saw from Harbor Freight (adjusted to cut square)

8" buff wheel powered by a 1/3 HP 1725 rpm motor (with green and white rouge)

Beaumont Metal works KMG-PL Grinder with 8x2 contact wheel, Knife Dogs small wheel attachment w/ .75" wheel, and of course the platen attachment and tool rest.

Foley 6" bench grinder and 4th generation Drill Press

Assorted Belts from USAknifemaker.com

And of course some steel from NewJerseySteelBaron.com (440-C, 154-CM, 1084, and 52100)

I have a question regarding the steel, the 1084 and 52100 arrived pretty warped along the length of the steel bar. Should I be worried about this waviness, is it normal? If it is normal I assume I will have to straighten any blanks I cut from it, any suggestions on how to accomplish this?